Leveraging Labeling & Coding Technology for High-Speed Beverage Production

When you grab a beverage, the first thing to catch your eye is often the label. But beyond the eye-catching design, there’s a lot at stake in the world of product and packaging labeling. For beverage manufacturers, these labels are more than just aesthetic choices—they’re pivotal components in compliance, branding, and consumer engagement. Let’s explore the essential considerations for getting those labels just right on primary, secondary, and tertiary packaging.

Regulatory Compliance: The Legal Pour

Different regions have their own sets of regulations governing what’s required on beverage labels. In the U.S., for example, the FDA mandates comprehensive information, including ingredients, nutritional facts, and allergen warnings. Missteps here can lead to costly recalls or fines, so staying updated with the latest guidelines is crucial. It’s essential to know the labeling requirements specific to your products and work with experts to make sure your labels meet current regulations.

Prime Performance: Boosting Accuracy and Reducing Errors

In beverage manufacturing, the need for accurate labeling and coding is paramount. In order to meet regulations and prevent recalls, beverage products need clear and consistent labels. It’s important to choose reliable label applicators and labels with the right adhesives, as well as permanent marking solutions. Having the right labeling equipment is critical for beverage manufacturers, especially as production speeds increase.

Traceability: Navigating the Beverage Jungle

In the event of a product recall, traceability is your best friend. Effective coding systems allow you to track products through their lifecycle—from production to the end consumer. This transparency is not only vital for recalls but also for building consumer trust. QR codes, RFID tags, and other coding solutions enable seamless tracking of product information. With dynamic barcodes or QR codes, consumers can instantly access a product’s journey from production to retail, strengthening brand trust and reputation.

Sustainability: Eco-Friendly Cheers

Sustainability is a growing focus in the beverage industry. ID Technology, along with other ProMach Labeling & Coding brands, supports eco-friendly labeling operations by using optimized printing processes and materials that reduce waste. Smart labeling and improved inventory management also help minimize overproduction, leading to more efficient supply chains and reduced environmental impact. Modern consumers are eco-conscious, and sustainable packaging can set you apart in a crowded market.

Technology and Automation: Perfect Pairings for Efficiency

Leveraging the right labeling and coding automation technology improves efficiency and accuracy for beverage manufacturers. The higher the production output, the more important it is to have reliable labeling solutions that can keep up with the line performance. This is where ProMach Labeling & Coding can help take your beverage lines to the next level with advanced technology to streamline operations and reduce human error.

Labeling & Coding Solutions For Beverage Lines

Precision in Every Drop

Coding & Marking Solutions for Primary Packaging

Every drink requires efficient coding and marking for beverage manufacturers to meet production demands, ensure compliance, and maintain product quality across diverse packaging formats like bottles, cans, cartons, and shrink wraps. ProMach’s Labeling & Coding inkjet and laser coding solutions deliver high-speed, reliable, and versatile printing of critical information on primary packages, such as expiration dates, batch codes, and nutrition information. We offer Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), and Laser Coding solutions for high-speed beverage production environments that accurately and reliably print information with ease. By integrating these advanced solutions, you can remain competitive, compliant, and efficient in a rapidly evolving market.

Continuous Inkjet (CIJ) Coding Solutions

ID Technology’s Citronix Continuous Inkjet (CIJ) Printer ensures accurate coding of expiration dates, batch numbers, and other critical information on a wide range of primary packaging materials, including bottles, cans, and cartons. Offering exceptional print quality and consistent performance, the Citronix CIJ printer is a versatile and reliable solution designed to meet the high-speed coding demands of the beverage industry.

Built for efficiency, the Citronix CIJ printer features a user-friendly interface for easy setup and adjustments, along with automated maintenance to reduce downtime. Designed to meet the demands of high-speed production, it enables beverage manufacturers to enhance traceability, ensure compliance, and maintain efficiency while minimizing operating costs.

- High-Speed Printing – Capable of printing sharp, legible codes on fast-moving production lines to meet the demands of high-volume beverage manufacturing.

- Versatile Substrate Capabilities – Supports coding on a variety of materials, such as glass, plastic, aluminum, and cardboard, making it suitable for diverse beverage packaging needs.

- Minimal Maintenance and Downtime – Designed with automatic maintenance features and quick-change consumables to maximize uptime and ensure uninterrupted production.

- Operator-Friendly Operation – Intuitive interface and remote connectivity options allow easy setup, monitoring, and control for efficient coding processes.

Permanent Tamper-Proof Laser Coding Solutions

The ID Technology Spark Laser Coder is a high-speed, non-contact coding solution for the beverage industry. The system provides high-resolution coding for critical information like batch numbers, expiration dates, and logos, while eliminating the need for inks and solvents, reducing waste and operational costs. Using laser technology, it creates precise, permanent marks on a variety of packaging materials, such as glass, plastic, and metal, ensuring durability and legibility.

The Spark Laser integrates smoothly into production lines, offering continuous, low-maintenance operation with minimal downtime. Its ability to produce permanent, high-quality codes at high speeds helps optimize production while meeting market demands. With an eco-friendly design and no consumables required, the MACSA Laser provides a sustainable and reliable solution for beverage packaging.

- Ultra High-Speed Efficiency – Seamlessly integrates into fast-paced beverage production lines, providing precise and permanent coding without disrupting the operational flow.

- Sustainable & Cost-Effective – By eliminating the need for inks and solvents, the Spark Laser reduces operational costs and environmental impact, offering a cleaner, eco-friendly solution.

- Low Maintenance, High Reliability – Designed for minimal downtime and maintenance, the Spark Laser ensures consistent, uninterrupted performance, maximizing production uptime.

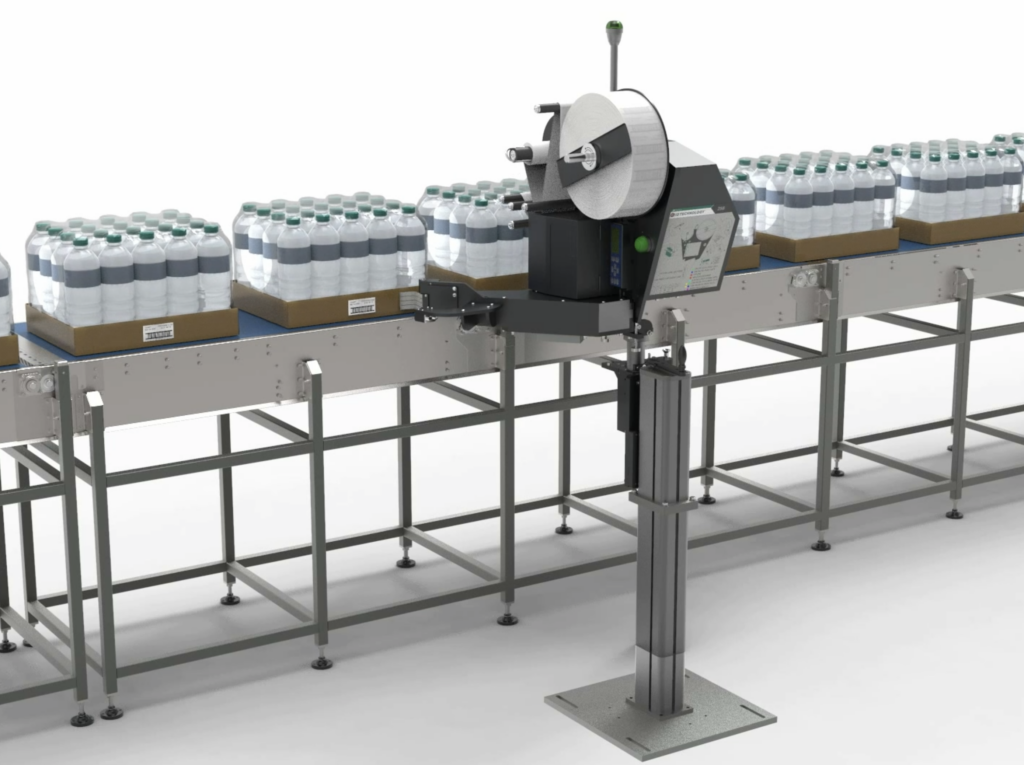

The Need for Speed

Secondary Labeling that Keeps Your Beverage Business Moving

When it comes to secondary packaging, ProMach Labeling & Coding offers a variety of printer applicators and high-resolution inkjet printers to apply vital information to cases, trays, and boxes. ID Technology’s high-speed labeling and coding systems offer a powerful and flexible solution, eliminating bottlenecks, reducing errors, and maintaining regulatory adherence. Our adaptability to varying packaging types, case and tray sizes, and label formats ensures beverage manufacturers can seamlessly adjust to changing production volumes and market demands—empowering them to stay competitive and ahead in a fast-paced industry.

Fast So You’re Not Furious

Combining speed, safety, and simplicity, the 258 Printer Applicator from ID Technology is a superior solution for high-speed case and tray labeling. Engineered to outperform competing systems, it eliminates compromises with innovative features and seamless integration into secondary case and tray packaging production lines.

Using patented CrossMerge® Applicator technology, the 258 decouples print speed from applicator speed, enabling slower, higher-quality printing while applying labels up to 50% faster than the competition. This advanced design ensures superior throughput without sacrificing precision.

- High-Speed Labeling – The fastest print and apply labeling machine in the industry for side-apply applications.

- High Print Quality – Barcodes are printed and applied in the preferred orientation, eliminating the need to slow down or stop for label application.

- Label Optimization – Labels are printed along the narrower dimension, allowing for more labels per roll and reducing replenishment time.

- All-Electric Operation – It’s all-electric, reducing operational expenses by eliminating the need for compressed air and further simplifying integration into new and existing production lines.

Combining Precision and Performance with Flexibility

In the beverage industry, where speed, accuracy, and flexibility are paramount, the 265 CarbonFlex Printer Applicator delivers unparalleled performance. By combining speed, precision, and flexibility, its modular design allows for seamless integration and utilizing advanced patent-pending CarbonFlex applicator technology to achieve consistent and accurate label placement on various surfaces, even under imperfect product handling.

Supporting a wide range of label sizes and labeling capabilities, including front, side, front and side, and corner wrap, the 265 CarbonFlex offers manufacturers the flexibility to meet evolving market and production line labeling demands. The 265 CarbonFlex is not just a labeling solution but a strategic investment in quality, efficiency, and scalability for beverage manufacturers.

- High-Speed Precision – Ensures accurate label placement at exceptional speeds, meeting the demands of high-volume beverage production lines.

- Labeling Flexibility – Single and multiple panel labeling solution, even under imperfect product handling, make it ideal for cases, trays, and pallet labeling.

- Safe for Operators – The low-mass applicator is extremely safe for operators, eliminating the risk associated with high-mass applicators and pinch points.

- Modular Design – Simplifies ease of use and service for production line labeling requirements change.

High-Resolution Printing for Corrugate Cases and Trays

The ClearMark HR High-Resolution Inkjet Printer from ID Technology is a cutting-edge solution for printing on cases, trays, and boxes in the beverage industry, delivering superior print quality and operational efficiency for primary and secondary packaging. With its ability to produce sharp, high-resolution text, barcodes, and graphics, ClearMark HR ensures accurate and legible coding to meet industry standards and regulatory requirements. Its advanced inkjet technology enables seamless printing on porous corrugated surfaces, offering versatility across a variety of packaging materials used in the beverage sector.

Designed for high-speed production environments, the ClearMark HR enhances efficiency while reducing downtime with its reliable, low-maintenance operation. The printer’s intuitive interface and robust construction simplify integration into existing production lines, ensuring consistent performance even under demanding conditions. By combining exceptional print quality, durability, and ease of use, the ClearMark HR is an essential tool for beverage manufacturers seeking to improve traceability, branding, and overall production efficiency.

- High-Resolution Printing – Ensures sharp, legible text and graphics for enhanced readability and compliance even in the most challenging and harsh environments.

- Compact Design – Allows for seamless production line integration in even the tightest of line spaces.

- Operator-Friendly Low Maintenance – Designed for reliable, long-term performance with minimal maintenance.

- Cost Efficiency – Reduces overall cost per print and total operating costs while delivering exceptional print quality – Eliminating the need for pre-printed materials.

Efficiency Stacked High

Tertiary Packaging Labeling Solutions that Deliver

ProMach Labeling and Coding offers beverage companies advanced tertiary and pallet labeling solutions that ensure compliance with GS1 standards, improving efficiency and meeting industry regulations. Our systems print and apply GS1-compliant barcodes and data, providing accurate traceability throughout the supply chain, simplifying inventory management, supporting product recalls, and improving logistics.

In addition to compliance, our automated labeling solutions reduce the need for manual work, minimizing human error and improving safety on the production floor. By streamlining the labeling process and reducing physical strain, our systems enhance workflow efficiency and reduce the risk of workplace injuries. This helps beverage companies improve safety, compliance, and operational effectiveness.

Pallet Labeling, Perfected

ID Technology’s 265 CarbonFlex Printer Applicator and Panther’s Predator Printer Applicator are high-performance labeling solutions specifically designed for pallet labeling in the beverage industry. These systems are built for high-speed production, ensuring precise and consistent pallet label application and enhancing efficiency and accuracy throughout the supply chain. They can handle a variety of materials and packaging types, making them adaptable solutions for different pallet configurations and beverage packaging formats.

- GS1 Compliance Labeling – Ensure full compliance with GS1 standards, providing accurate barcodes and product data for seamless inventory management, traceability, and regulatory adherence across the supply chain.

- Accurate Labeling Automation – Our automated labeling solutions reduce manual labor, ensuring faster and more accurate labeling on high-volume production lines, minimizing downtime, and improving operational efficiency.

- Safety and Efficiency – Reduce operator intervention, minimizing the risk of errors and enhancing safety in the workplace while optimizing labeling throughput.

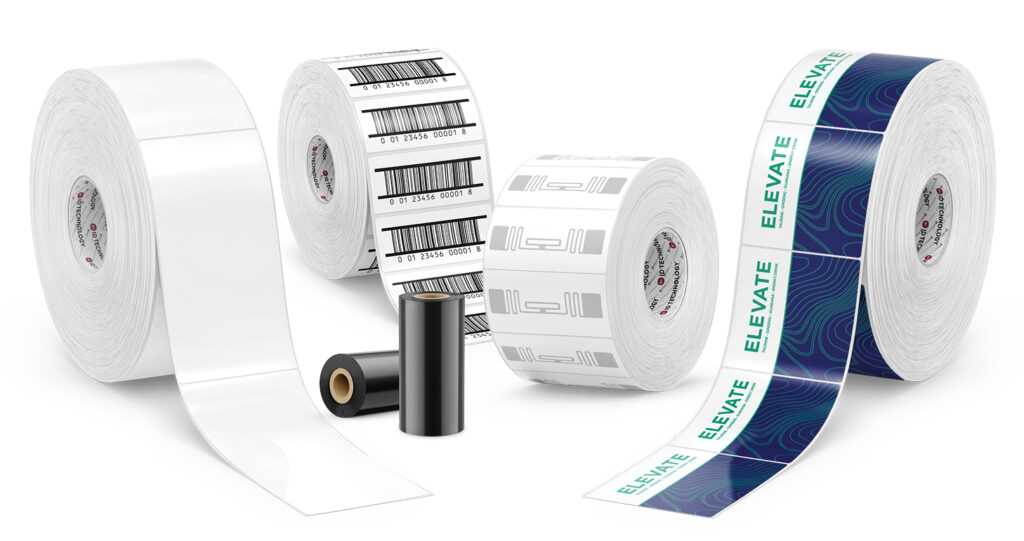

Labels That Seal the Deal

Quality Labels for Primary, Secondary, and Tertiary Packaging

Beverage companies choose ID Technology for label manufacturing and converting needs because of our unmatched expertise, advanced capabilities, and commitment to quality. We provide high-performance labels tailored to meet the unique demands of the beverage industry, ensuring durability, compliance with regulatory standards, and vibrant branding that stands out on shelves. From pressure-sensitive prime and decorative labels to blank and shell labels, our versatile solutions are designed to meet the needs of any packaging type, including bottles, cans, cases & trays, and pallets.

With 10 label manufacturing facilities across North America and extensive production capabilities, we’re uniquely positioned to provide additional benefits not found in other label producers. Our state-of-the-art production provides quality stock and custom labels, no matter your need. You won’t find another labeling automation manufacturer that comes close to offering this type of label service and support for the systems that utilize our own label stock.

- Expansive Label Manufacturing Capabilities – High-volume blank & shell, prime & decorative, and Specialty RFID and industrial labels for primary, secondary, and tertiary labeling applications.

- National Presence, Local Support – With 10 North American label manufacturing facilities, we’re closer to you, resulting in reduced shipping time and expenses.

- Added Value Features – Subtle details make all the difference, and we build extra value into every roll of labels we produce – all designed to make things easier for your operations and help your productivity.

See what separates us from the competition – Learn more about the ID Technology Advantage and our added value features.

A Smart Investment for the Beverage Industry

In the competitive beverage market, manufacturers need efficient operations and regulatory compliance. ProMach Labeling & Coding is a trusted partner with solutions to drive efficiency and innovation, enhance traceability, reduce errors, and protect brand integrity. ID Technology offers adaptable and innovative labeling solutions to stay ahead of trends and prepare for the future. Our solutions automate processes, meet regulatory demands, and ensure quality and compliance, paving the way for a sustainable and transparent future.

To optimize your labeling and coding processes, contact ID Technology today.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.