Here at ID Technology, we currently operate seven label plants – five in the US and two in Canada – so we make a lot of labels.

Here at ID Technology, we currently operate seven label plants – five in the US and two in Canada – so we make a lot of labels.

Many of the labels we sell are beautifully printed, using flexo or digital technology, ready to be applied to our customer’s products. We also make a lot of blank labels that are used on print/apply labelers or tabletop printers – these are usually applied to logistic items such as shipping cases, shrink-wrapped trays and pallets. The barcodes that are printed on the labels are used to ensure the packages are correctly routed through the supply chain to their final destination.

The business for blank thermal and thermal transfer labels is very competitive and there are lots of companies to buy from. When you look at blank labels, it is easy to think that they are all the same and it is ok to buy the cheapest. This is far from correct and here is an example that shows this:

A distribution center for a large sports products company uses our 350 high-speed printer-applicator system to print and apply labels to products of various sizes. While the equipment was working really well, the customer was having difficulty maintaining good print quality (a barcode scanner installed right after the labeling system would often reject the barcodes) and also was having to replace printheads more often than would normally be expected.

Our local service tech, Michael, called at the plant to check out the situation and found nothing amiss with the equipment, but the customer was correct in that the print quality wasn’t as good as it should be. To be able to produce scannable barcodes the print engine darkness setting was turned to maximum. Clearly, something wasn’t quite right.

The customer wasn’t using ID Technology labels – instead was using direct thermal labels from a local supplier. Obviously, we want to sell our labels to everyone using our labeling equipment, but we understand that this isn’t always going to be the case. ID Technology labeling equipment will work happily with any high-quality label stock.

To get an understanding of what was happening, Michael swapped the customers roll of labels for a roll of ID Technology direct thermal labels and carried out some test prints. The results were very interesting.

There are two important settings in the thermal print engine that can define the print quality. The print speed which is measured in inches per second (IPS) and the print darkness, measured on a scale of 0 -30 with 30 being maximum darkness. This 350 labeling system is using a Zebra ZE500 thermal print engine that has a maximum print speed of 12 IPS. Because of the high-speed nature of the line, this is the speed setting being used. Generally, it is more difficult to get good print quality at high print speed settings.

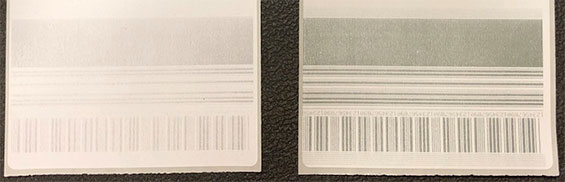

Michael ran test prints of the original label and the ID Technology using a low darkness level of 5.0 at the 12 IPS speed:

It is quite clear that the customer’s original label needs more energy applied to generate an image.

As the next step, the test was repeated, using settings that would produce acceptable print quality to run in production. With the original label, the darkness setting needed to be set to 30.0 (the maximum value) to achieve consistently high-quality text and barcodes. With the ID Technology label, good results were easily obtained with a darkness level of 20.0.

What does this mean for the customer?

Our labeling systems are designed to produce excellent barcode quality and there is no reason that barcodes should fail to read after the label is applied. We don’t like having to run the printers at the maximum darkness setting – this reduces the lifetime of the printheads and allows no adjustment to increase the darkness setting which is often needed as the printhead wears.

The labels that our customer was using, needed more energy to produce the image than the ID Technology label and it was also noted that they had a slight gloss finish. We wondered if this surface finish was causing reflections that might be affecting the barcode scanner.

The message here is that while it might be tempting to buy low cost, poor quality labels, this is very likely to cause downtime on packaging lines and increased maintenance costs on labeling and printing equipment. We hugely encourage our customers to use good quality labels – either the ones we make or from another reliable supplier.

Why use ID Technology Labels?

Labels that are made in any of our label converting plants are engineered to work exceptionally well on ID Technology (or any other) print-apply equipment. We use only top quality materials and have total control over the die-cutting process on our modern converting equipment.

In addition, ID Technology labels come with some special added-value features such as:

- Lifetime equipment warranty – in many cases, we offer a limited hardware warranty for our customer’s labeling equipment for as long as our labels are used.

- Clear leaders and trailers – we can remove the labels from both the start and end of the label rolls. This makes loading the labels easier and also allows fast detection of the end of the label roll.

- Label/Ribbon Kits – for customers using thermal transfer technology, we can provide kits with labels and ribbons of matched length. This ensures that labels and ribbons can both be replenished at the same time, reducing the need for additional stops.

You can read more about our “Auto Series” labels here.

How can ID Technology and ProMach help you meet your objectives for your labeling operations? Contact us today at 888-438-3242 Option#3. You can also email me at dholliday@idtechnology.com. We’ll be sure to get you in touch with an expert, right in your area!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.