It’s a New Year with new resolutions. Many have decided to get healthier, spend less and even to be more organized. Why not include your labeling equipment in that resolution? There are several easy things you can do to ensure a long life and greater efficiency for your labeling equipment.

When it comes to our labelers, there are some simple no-cost things you can do to make sure your machine is operating properly for the life of the labeler. As a leader in the pressure sensitive labeling market, EPI has gained much experience from working with market leaders in snack food, confectionery, coffee, and consumer products industries. We are constantly developing new products and better methods to solve labeling problems to ease the burden on production personnel.

Here are some recommendations we have for all our clients on how to keep your labelers running like the day they were installed.

Cleaning and Sanitation

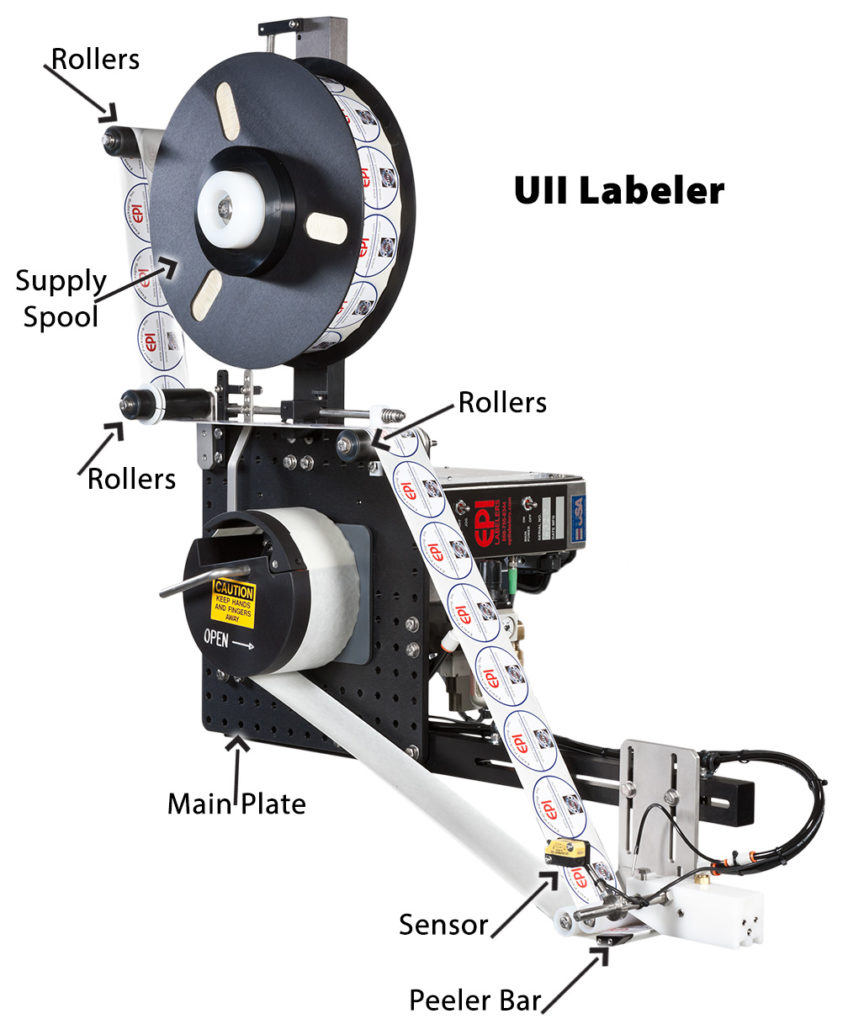

Wipe down the following with a plant-approved, liquid food-grade cleaning agent using a cloth and then wiped dry with another cloth:

- Main Plate

- Peeler Bar

- Rollers

- Supply Spool

It is critical the peeler bar and the applicator are clean of adhesive. The Label Sensor should be wiped clean with a dry cloth also.

The cleaning for the Top Plate, Supply Spool, and Label Sensor should be done anytime machine production is stopped and at a minimum once a day.

EPI Labelers are designed to work within a normal food-packaging environment. If the labeler is operated in a dusty area, be sure to wipe the machine off as much as possible.

Don’t Forget!

- Cover the machine and remove power if equipment above or around it is being cleaned, especially if water is being used in the process.

- Clean the labeler after surrounding equipment has been sanitized.

- CAUTION: DO NOT wet down this machine or directly hit it with an air hose. Damage to the unit or personal injury may occur.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.