We excel at taking information and placing it on products and packaging. And our interactive production line interface showcases how our best-in-class labeling and coding solutions can benefit and boost your packaging operations.

Whether you’re needing solutions for your primary, secondary, or tertiary packaging, we’ve got you covered.

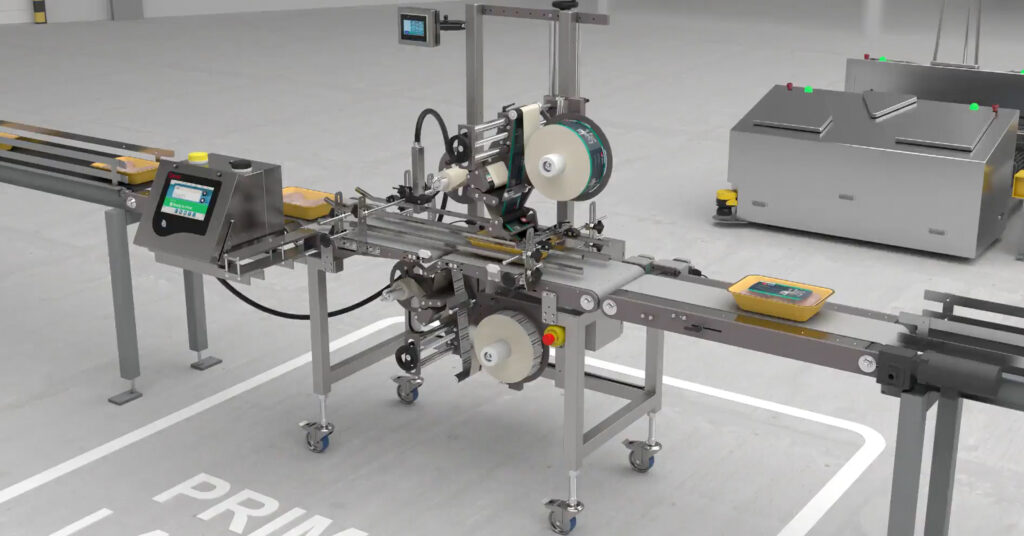

Primary Packaging Solutions

From standalone labelers to completely integrated pressure-sensitive labeling systems, our label applicators will apply your decorative/prime labels to products and packaging fast, accurately, and reliably – every time.

Each system can also be configured to include secondary coding solutions from continuous inkjet (CIJ), thermal inkjet coding (TIJ), lasers, or thermal transfer overprinters (TTO). These solutions clearly and consistently mark your items with date, lot, or other pertinent information – on the labels or directly to the packaging themselves.

Secondary Packaging Solutions

Our secondary labeling and marking solutions feature best-in-class printer applicators and high-resolution inkjet printers for applying labels or printing information to your cases and trays.

For example, our high-speed ID Technology 258 printer applicator applies labels with A Grade barcodes to a single or opposing sides of an item at rates up to 120 items per minute.

For performance and flexibility, our ID Technology 265 printer applicator or Panther Predator applies labels with A Grade barcodes to the front, side, front and side, or around the leading corner with our innovative CarbonFlex™ applicator technology, even with imperfect product handling or items with irregular surfaces.

Each of these printer applicator solutions can be configured in a ZeroDowntime application so your line does not have to stop when it’s time to replenish labels. That equates to greater OEE and throughput in your operations.

For marking on corrugated cases, our ClearMark HR™ is a high-speed, high-resolution inkjet printer that provides a clear, crisp imprint of barcodes and other information directly to the surface of your item.

Tertiary Packaging Solutions

For labeling pallets, our printer applicators provide safe, reliable, and flexible solutions for applying labels to single or multiple sides of the pallet.

The Panther Predator printer applicator or ID Technology 265 printer applicator applies labels with A Grade barcodes to the front, side, or front and side of the pallet with our innovative CarbonFlex™ applicator technology, even with imperfect irregular surfaces from the stretch wrapping process.

For even greater flexibility in your operations, our printer applicators can be mounted to our auto-height servo stand that provides the ability to label pallets of variable heights, in motion, on single or multiple sides of the pallet.

The auto-height stand features programmable variable speed adjustments – up to 12″ vertical adjustment per second and 53″ total range. And the label application position can be set to a fixed location on the item, or determined by a sensor. The stand is direct-drive, eliminating the need for complex pneumatics, belt drives, or gearboxes.

Label Replenishment & Data Control

Our solutions aren’t just centered around equipment, too. We look at your entire operations and work with you to provide solutions that reduce downtime and improve efficiencies in your operations.

This interactive resource demonstrates what happens when you have to stop for label replenishment for your printer applicators, both with and without redundancy in your secondary packaging area. This reinforces how we can help you improve your throughput and achieve greater ROI with our ZeroDowntime solutions.

And as a single-source provider of both equipment and labels, we have eight label production facilities across North America to provide you with high-quality decorative/prime, blank, shell, and specialty labels. Check out the ID Technology advantage of our label capabilities to see how we can serve you nationally with a local presence. If you’re not using our labels, it’s probably costing your business more than you think.

Additionally, our data control systems allow you to manage the information you are placing on your products and packaging from a centralized location – with non-proprietary software – easily and efficiently.

Learn More

Take a test drive with our interactive production line and see for yourself how our ProMach Labeling & Coding solutions can help improve your bottom line.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.