As a manufacturer of pet foods, you know how your customers love their furry, feathered, or scaled friends and want the best for them.

Labeling and date coding for your packaging is integral to your product presentation, ensuring your finished product looks good, conveys information clearly, and travels through the supply chain without disruption.

This is where ProMach Labeling & Coding comes in, with innovative labeling and coding solutions that help pet food manufacturers provide high-quality packaging while enhancing efficiency on the packaging line.

Premium Labeling & Coding Solutions – We Shih Tzu Not

Quality Labeling & Coding for Primary Packaging

Regardless of the package format you use for your pet food products, bags, pouches, cans, and more, you must print date codes, lot numbers, and other production codes onto the package.

Of course, there are some challenges:

- The printed codes on the package need to be as clear and easy to read as possible.

- Being confident that the variable information printed is always 100% correct.

- If your cans or pouches pass through a retort system, you might need to utilize color-change inks for the variable printing to show the process has been completed.

- Using legacy, maintenance-intensive coding systems can make it challenging to keep your packaging line efficiency as high as you need.

ProMach Labeling & Coding offers a comprehensive lineup of coding technologies that solve all these issues.

Our CIJ continuous inkjet, TIJ thermal inkjet, laser coders, and thermal transfer TTO printers, are all designed to be simple to use, with easy maintenance. They produce excellent print quality, making your printed codes crisp and easy to read. Our ID Technology Control apps, ensure that the correct data is sent to each printer every time, reducing the possibility of human errors.

Continuous Inkjet

Our CIJ Citronix printers are known in the industry for being system to use, and you don’t need to buy expensive service contracts.

For products in cans or pouches that need to go through a retort process, we can supply color change inks that react to the temperature change, showing that the package has successfully gone through the process.

TIJ

Thermal inkjet (TIJ) printers from ID Technology and Code Tech require almost no maintenance, produce excellent print quality, and can be equipped for use in harsh environments.

Laser

Macsa laser coders operate without the need for consumables and are often an excellent solution for adding variable codes to bags, pouches, and other types of packaging.

TTO

Thermal transfer overprinters (TTO) are versatile in that they can print in both continuous and intermittent modes and have a print area up to 5 inches wide to print more information, such as nutritional panels.

As well as having best-in-class performance, all of our coding systems are compatible with our ID Technology Control software apps, based on the NiceLabel platform. This lets you control all the printing systems on your packaging line from a central workstation.

Labeling for Pet Food Packaging

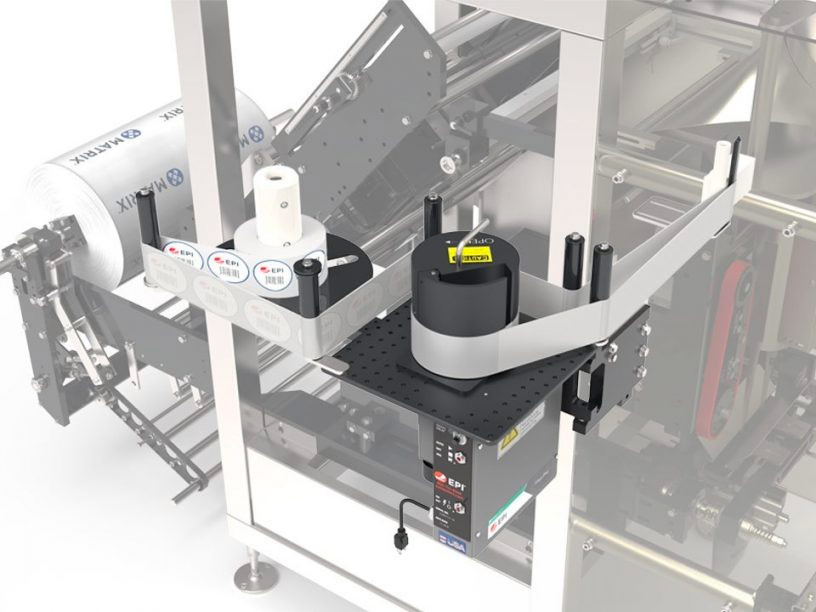

Do you need to add labels or coupons to your flexible packaging?

For this, our EPI Flex-Pac labeling system is ideal, designed to be easily integrated into your packaging machine and be simple to use, operate and maintain.

Check out our rental option if you need labeling capacity for short-term production, such as a marketing campaign.

Quality Labeling That’s Not Ruff Around the Edges

Fast and Accurate Labeling for Secondary Packaging

While your secondary packaging, such as shipping cases and shrink-wrapped trays, doesn’t usually involve consumer interaction, it is essential to label it correctly to ensure smooth travel through the supply chain and meet industry and retail customer standards.

Some of your challenges include:

- The correct number of barcodes on each package in the locations your customers require.

- Ensuring that the applicable barcode formats are printed to GS1 quality standards to avoid customer chargebacks.

- Being confident that the barcode data and other print on your package are correct every time.

- Ensuring that your labeling and printing systems can produce the required quality while also helping you maintain the efficiency you need from your packaging line.

Labeling and printing systems from ProMach Labeling & Coding meet all these challenges. Our team works with you to ensure your barcode labeling complies with your customer’s needs and industry standards.

Our secondary packaging products are designed to enhance productivity and reduce downtime while producing excellent barcode print quality, keeping your supply chain moving and eliminating customer chargebacks.

Using NiceLabel-based Control apps, we also connect directly to your system database, removing the potential for human error and incorrect information on your labels.

Print and apply labeling and direct-to-case printing are the two most popular ways to add variable information and barcodes to secondary packaging. We have you covered with both.

Print and Apply Labeling

ID Technology print and apply labeling systems are the market leader in North America. They are designed to maximize throughput and keep you in compliance with industry and customer barcode mandates.

Products such as the 258 CrossMerge™ and 265 CarbonFlex™ provide the largest number of labels per roll, enhanced barcode print quality, and operator safety features.

As with the coding systems, all our print and apply labelers are compatible with the ID Technology Control apps, giving complete control of your labeling and coding systems from a single workstation.

Direct to Case Printing

Our ClearMark™ HR printing system is the latest generation in piezo inkjet print technology. This system provides an exceptionally low cost per print, consistent GS1 barcode grades, and easy maintenance.

ClearMark HR can often print all the information on the case, reducing the need to manage inventories of pre-printed materials.

The Best Pedigree in Pallet Labeling

Reliable, Efficient, and Safe Pallet Labeling

Labeling the pallet is often the final operation on a pet food packaging line, and the labels must comply with industry GS1 standards and your customer’s labeling mandates. It is crucial that the label is printed correctly, with all the correct data, and applied in the right locations on the pallet.

How do you label your pallets?

- Use a tabletop printer to print the labels and have your forklift driver risk injury by constantly dismounting to fetch and apply the labels.

- Have other operators in the area taking the time to deal with the labels and having to work in an area with active forklift traffic?

- Face human error challenges when manually applying labels to pallets.

Automating your pallet labeling with our ID Technology and Panther systems provides safety for your forklift drivers and other operators and ensures the correct label is applied to the right pallet every time. The CarbonFlex™ applicator blade is designed to improve safety for anyone in the area.

Our ID Technology Control apps can get the data correctly sent to the printer (and manage the other printing and labeling systems on the line), improving data integrity and reducing the possibility of human error.

Fresh Ingredients Demand Fresh Labels

Quality Labels for Primary & Secondary Packaging

Labels are often taken for granted, but recent years have shown that there are several challenges:

- Longer lead times due to label material supply chain issues.

- Increasing shipping costs.

- Distance between the label production site and the point of use increases the cost and complexity of label logistics.

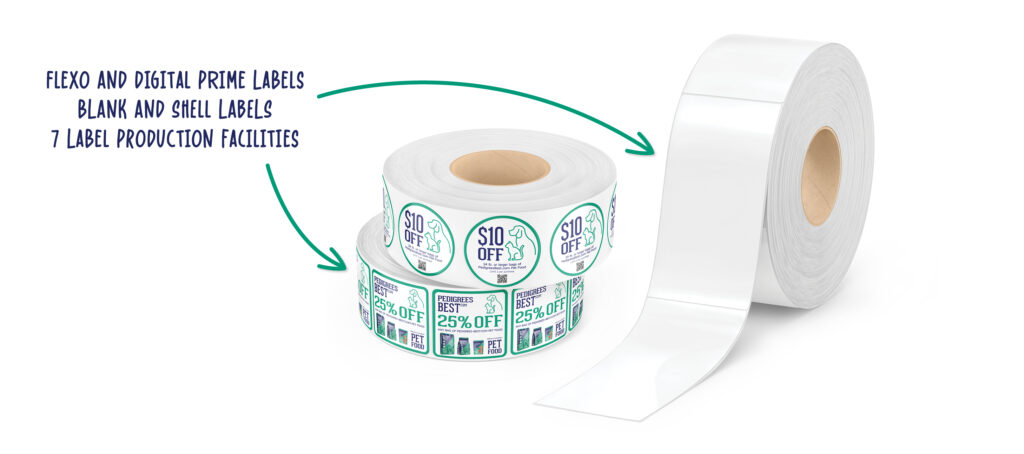

ID Technology is a leader in label production for prime product labeling and secondary packaging.

Our large volumes of purchases and excellent relationships with material manufacturers allow us to continue to supply our high-quality labels to customers, even in times of supply chain disruption.

With seven label production plants across North America, we are your local label company with a national reach. This allows us to produce your labels at our closest location to you, reducing shipping costs and delivery times while helping meet sustainability goals.

Whether you need printed labels for your primary package, or blank direct-thermal or thermal-transfer labels for your secondary packaging or pallets, there is an ID Technology label solution that will work for you.

In Conclusion

ProMach Labeling & Coding has a range of innovative solutions to meet the variable information needs of pet food manufacturers, from date and lot/batch codes to nutritional panels and barcodes. With their cutting-edge technologies and ID Technology Control software apps, pet food manufacturers can ensure their products are appropriately labeled, traceable, and meet all industry and retail customer standards.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.