Let’s say you’re an expert at baking a rather complicated cake 🍰

No need for any written instructions, you’ve done it many times, and everything is right in your head.

But what if you want to share your culinary creation with someone else so they can make their own?

I’m sure you’d write down the list of ingredients they’d need and add some instructions to get them started. Then, yes, you’ve made a recipe.

Labeling equipment is no different.

When setting up a new production run, several settings often need to be made so that accurately labeled product is produced as quickly and efficiently as possible.

You might have this process down to an art and don’t need any help. However, others might appreciate ways to simplify this setup process and where the recipe feature for the MFlex™ labelers can help.

When setting up an MFlex labeler for a new production job and everything looks perfect, save the settings as a recipe.

Once this is done, the next time you need to run that product, choose that recipe from the list, and all the settings are correct where you need them. Since all MFlex labelers have a singular HMI that controls everything, there is only one simple recipe screen to deal with.

You make the mechanical adjustments, such as guide rails, label height, etc., and the labeler is ready to run.

Using the pre-set recipes to quickly set the MFlex, works so well because of the sophisticated synchronization of all the machine modules.

The speed setting of each module, along with sensor delays, is part of the saved recipe. So regardless of how many product handling modules and how many labeling heads are on your machine, everything is ready to go, all in perfect sync.

The recipe feature is part of our MFlex goal to be simple and sophisticated.

We worked behind the scenes on sophisticated controls to make MFlex simple for your operators and maintenance team. The recipes to enable easier and faster setting up, are just one part of the total package.

Other key features include:

Syncing Outside the Box

Synchronizing label feed control with in-motion products is crucial to achieving consistent and accurate labeling results. We designed MFlex around an innovative motion control system with a closed-loop servo system that monitors and synchronizes all aspects of the machine modules. So the MFlex maintains complete control over the labeling process, even if the machine speed changes or stops completely while applying a label to your product or package.

Now that’s sophisticated.

Harsh Environment? Bring it On.

Damp or dusty production environments are not an issue for the MFlex. The system is built for IP65 protection, utilizing non-corrosive components and a welded stainless steel frame for

durability.

Now, that’s standard.

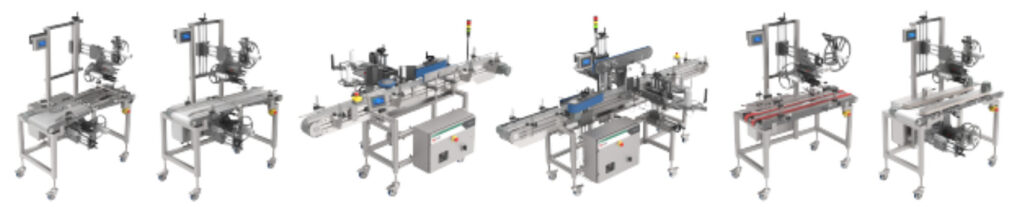

Meet The Mod Squad

Our full range of modular label applicator configurations makes the MFlex perfect for almost any type of product or package labeling your production requires. This flexibility also supports our singular design philosophy – system components are common across the entire suite of options, making routine service and support very efficient and straightforward.

To learn more about the innovative MFlex pressure-sensitive label application system and how it can improve your production operations, contact an account manager at epi@promachbuilt.com or visit the MFlex product page on EPI’s website: https://www.epilabelers.com/products/mflex-label-applicator-system/

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.