Two applications found on many packaging lines are the need to correctly seal the shipping cases after loading the products and then add the GS1 barcodes and other information needed for industry and customer compliance.

For some time, ID Technology has offered an integrated case taping and labeling system that combines a Wexxar BEL case taper with one of our print-and-apply labeling units – the CTL (Case Taper Labeler) family.

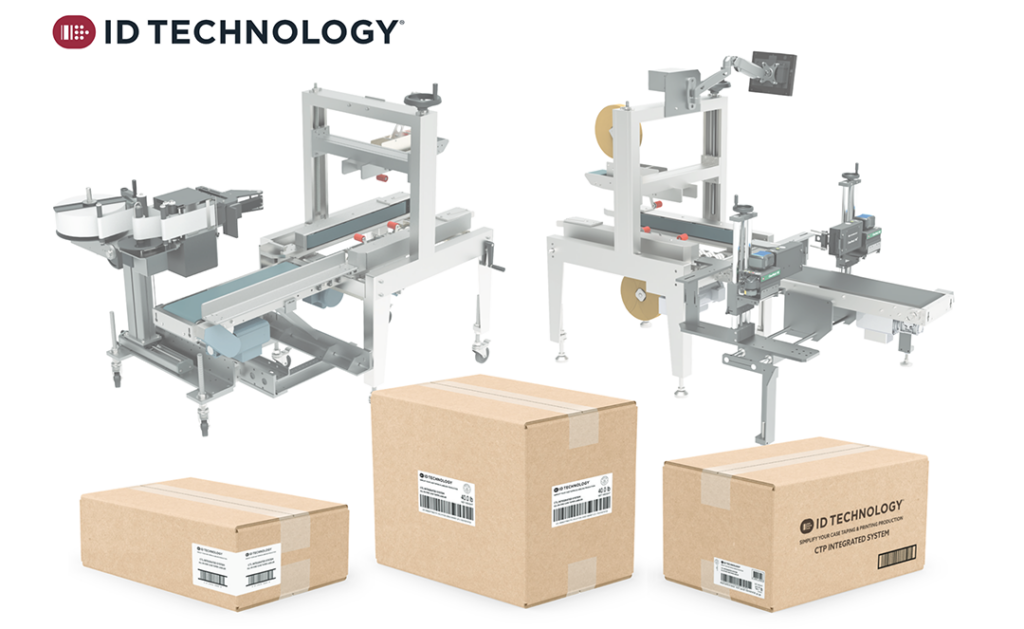

A new family member is the CTP (Case Taper Printer) introduces integrated case taping and printing, which is ideal for customers wanting to use an inkjet solution to add barcodes and variable information to the shipping cases.

Like its sibling, the CTP uses a case-taping system from our ProMach colleagues, Wexxar BEL – either the semi-automatic BEL 150 or the fully-automatic BEL 252.

Printing duties are handled by the ID Technology ClearMark™ HR direct-to-case inkjet system.

Key advantages of the CTP include:

- Smaller footprint than individual machines – saving valuable space on the packaging line.

- Fast changeover for different case widths – a single adjustment correctly positions both the case taper belts and the printheads, saving time and improving efficiency.

- The BEL taper’s twin belts ensure accurate case positioning every time. This is important to achieve the best print quality for text, graphics and GS1 barcodes.

- The ClearMark HR can print up to 8 inches high (using a pair of 4-inch wide heads) – this can eliminate the need to purchase and manage inventories of preprinted corrugated.

- ClearMark HR requires minimal maintenance and doesn’t need to stop for ink replenishment, adding to the OEE of your packaging line.

Both the CTL and CTP systems can be provided with an optional BEL 505, semi-automatic case erector and package station. This is an efficient all-in-one solution for lower-volume packaging operations.

Our family of case sealing and labeling/printing systems is just a part of our extensive portfolio of labeling and coding solutions for secondary packaging, bringing you innovative solutions to enhance your packaging operations.

Contact us at IDT@ProMachBuilt.com to get connected with your local ID Technology representative.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.