Leaner Labeling Automation

Secondary Packaging Labeling

Your protein products need GS1 barcodes applied to the secondary packaging to be tracked through the logistics chain and help with your FSMA traceability.

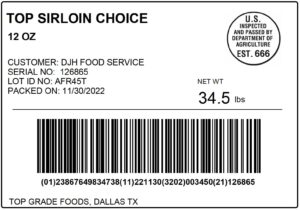

While many products need to have an ITF-14 barcode containing the product GTIN, the secondary packaging within the protein industry often needs to include a GS1 128 barcode containing additional data fields (example shown below).

With GS1 128 Barcode

Because the labels need to be printed with real-time data (production data and package weight), they are usually printed and applied to the shipping case right after the case has been filled with the product and sealed.

As always in the protein industry, the labeling equipment must operate in environments that can be cold and damp, sometimes subject to washdown procedures.

And, of course, protein companies continue to have to deal with labor shortages, manage production increases with limited resources, and the continuing growth in the number of SKUs.

In many cases, the production growth is expected to be handled on legacy conveyor systems that don’t have the most accurate product handling.

Best-In-Class Printer Applicators for Secondary Packaging

With decades of experience in providing labeling systems to the protein industry, two of ProMach Labeling and Coding’s product brands – ID Technology and Panther – are uniquely positioned to support secondary packaging labeling.

As a historical market leader for print and apply labelers in North America, we have a portfolio of systems engineered to handle the demands of protein processing companies. In addition, we provide nationwide and regional support to ensure that any assistance you require is always available.

Our lineup of print and apply labeling equipment is designed to minimize the need for operator and technical intervention – freeing your team to attend to other tasks on the line.

For example, the high-speed 258 print and apply system takes simplicity and ease of operation to a new level. The operator interface is a simple singular button, and the system’s intelligence takes care of many tasks that might need operator intervention with legacy labelers.

Using the innovative CrossMerge™ applicator module, the 258 reduces operator involvement. CrossMerge also reduces downtime by supporting more labels per roll and prints the barcodes in the correct orientation to ensure the best print quality, reducing the possibility of chargebacks for poor barcode quality.

The mounting hardware for the 258 is engineered to allow the labeler to quickly move away from the conveyor for label roll changes – making it easier for the operator and ensuring they are clear of moving conveyors.

Another highlight of our print-and-apply product line is the CarbonFlex™ applicator module, available on the ID Technology 265 and the Panther Predator labeling systems.

Our CarbonFlex technology utilizes a servo-controlled carbon fiber applicator to label one or two sides of a shipping case.

The 265 is incredibly forgiving of poor product handling, providing accurate and reliable label placement, even when the cases are slightly askew.

For additional safety, the applicator automatically stops if it touches anything unexpected, ensuring the system is safe for your operators to be around.

Like the 258 machines, the 265 with CarbonFlex prints the labels in the best orientation for maximizing the number per roll and consistently achieving top barcode quality.

These systems are designed to operate without the need for compressed air. In addition, both can be configured for zero downtime (using a pair of labelers) to maximize productivity on high-volume packaging lines.

If the location where your labeling takes place is particularly harsh, ID Technology can provide labeling systems engineered with environmental enclosures that can be completely sealed during washdown.

Blank Labels from ID Technology

ID Technology is also a leader in label production – both for prime product labeling and for secondary packaging.

With 10 label production plants across North America, we are your local label company with a national reach. All of our label plants are equipped to produce thermal transfer and direct thermal labels in large volumes, and we have pioneered innovative features such as clear leaders and trailers for the label rolls – making it easier to load labels to the print and apply machines and enhance equipment operation.

Our AutoSeries EX label is our latest innovation that uses a thinner liner and facestock to allow more labels per roll and very consistent die-cutting.

Finally, if you use ID Technology labels on our print and apply labelers, you might qualify for our lifetime limited equipment warranty.

Improve Your Protein Production with ProMach Labeling & Coding Solutions

By integrating our vast array of ProMach Labeling & Coding solutions in your protein operations, you get best-in-class printing and labeling systems, excellent support, and the opportunity to consolidate all the setup and data control into one integrated solution. That translates to greater throughput, increased efficiency, and a better bottom line.

To learn more about coding and labeling for protein products, please contact us at IDT@ProMachBuilt.com .

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.