When Your Reputation’s at Steak

Fast Accurate Product Labeling

If you work in protein processing, you’ll know that your package is hugely important and serves several functions:

It protects your product from when it leaves your packaging line until it arrives in the consumer’s kitchen.

The package needs to carry important information – ingredients, allergen disclosures, your plant’s EST number, date codes, production codes, and your UPC barcode.

Of course, your finished package is a crucial part of your company’s marketing, and branding – how the package looks on the shelf can determine your company’s image. It can help the consumer choose your package rather than competing ones.

The label on the package presents your company to your customers and is the finishing touch to your primary packaging.

How can you ensure that your labeled product truly represents your company while keeping your packaging lines running efficiently?

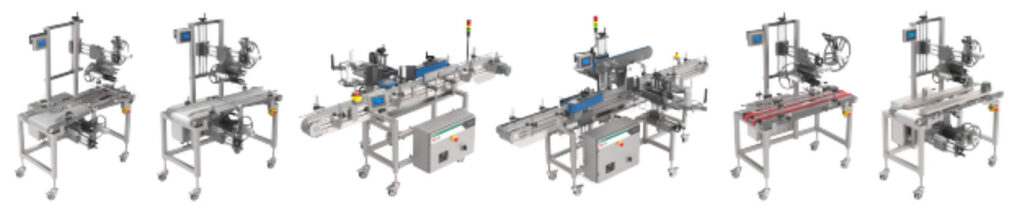

The MFlex™ Pressure-Sensitive Labeling Automation System

MFlex labelers are engineered with the needs of demanding protein processing companies in mind.

MFlex is a family of modular labelers that can handle the package types used for meat/poultry and other protein product packaging. The machines are constructed from standard modules that allow them to be configured to match the application exactly.

Using MFlex for fast accurate product labeling for your protein lines keeps your production moving.

Some of the special features included in every MFlex labeling system include:

IP65 Environmental Protection as Standard

Built with a welded stainless-steel frame and non-corrosive components, every MFlex meets IP65 standards, making it an ideal system for use in the conditions encountered in protein plants.

All motors, enclosures, switches, sensors, and connectors are IP65 rated – MFlex labelers are built to last, regardless of the operating environment.

Singular HMI Controller

Designed to be operator-friendly and reduce the need for extensive training, MFlex labelers have a single control point that keeps operator interactions simple and easy to learn. The most common functions are always instantly available; there is no need to use complicated menus to find what is needed.

For your maintenance team, the password-protected area provides comprehensive diagnostics to help with troubleshooting and issues.

To help with minimizing downtime for product changes, all the machine settings can be stored in a recipe for instant recall the next time that product is run.

Sophisticated Motion Control System

While MFlex is designed to be simple for your operators, behind the scenes, our sophisticated servo-based motion control system makes sure that all the machine modules are perfectly synchronized – all the time.

Having the conveyor, label feed, and product handling in perfect sync is the secret to accurate labeling – ensuring your product looks great in the retail store.

Other MFlex advanced benefits.

- Zero Downtime: For high-volume packaging lines, reducing downline is essential for efficiency and MFlex can be configured with additional labeling heads that eliminate the need to stop for label roll changes.

- Integrated Coding System: You need to add variable information date and production codes to your package, so we can configure MFlex labelers with an integrated coder – continuous inkjet (CIJ), thermal inkjet (TIJ), thermal transfer overprinter (TTO) and laser coders are all available.

The coding system can be installed to print on the label or directly to the package, depending on your needs.

- Integrated Print and Apply Labeling: One or more of the labeling heads can be integrated as a print and apply unit to reduce the inventory of pre-printed labels you need to manage.

A common example is to use the usual flexo or digital label on the top of the package (with your branding and marketing message) and print the bottom label on demand with the ingredients list, allergen warning, nutrition panel, and UPC barcode – right before it is applied to the package.

Preprinted or Blank Labels from ID Technology

ID Technology is also a leader in label production – both for prime product labeling and for secondary packaging.

With seven label production plants across North America, we are your local label company with a national reach. Our significant investments in digital and flexo label printing technology, as well as in pre-press systems, make us your one-stop provider for both labels and labeling equipment.

Improve Your Protein Production with ProMach Labeling & Coding Solutions

By integrating our vast array of ProMach Labeling & Coding solutions in your protein operations, you get best-in-class printing and labeling systems, excellent support, and the opportunity to consolidate all the setup and data control into one integrated solution. That translates to greater throughput, increased efficiency, and a better bottom line.

To learn more about product coding and labeling for protein products, please get in touch with us at IDT@ProMachBuilt.com .

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.