On-Demand Printing for Demanding Applications

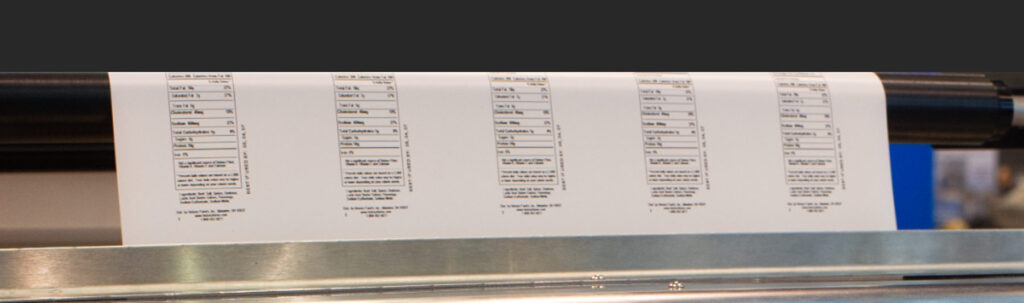

Secondary Printing on Packaging Film

For the packaging for your protein products, do you find that you often use the same film with just the product details changing?

If you have several SKUs that use this same package, you’ll find that you’re having to manage inventory of all the pre-printed material, which can complicate your inventory and supply chain.

What if you could buy generic printed film and print all the product-specific information right at the point of packaging? How would this affect your productivity and help with lean manufacturing concepts?

Not having to source and manage pre-printed packaging films would simplify your process and eliminate the waste of scraping inventory if the copy needed to change. In addition, changeover time between SKUs would be greatly reduced by not having to change the roll of film between each job.

Here’s where our ProMach Labeling & Coding solutions come in – by using our thermal transfer systems on your flexible packaging machines, you can switch to an all-digital workflow for your package printing.

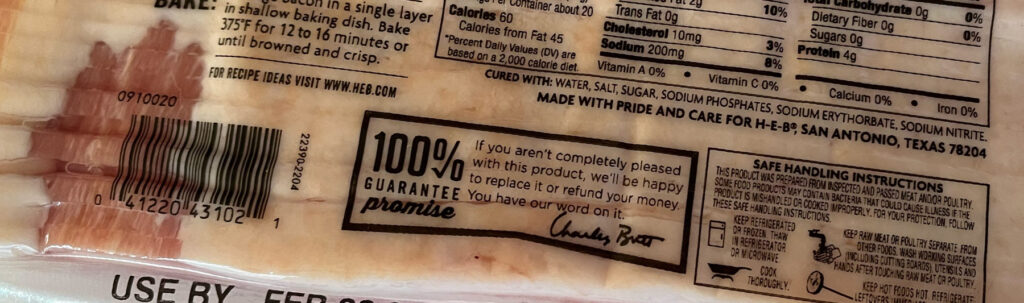

This approach allows you to order preprinted packaging film that includes all features that don’t change – items such as your logo, company information, your address, and other contact information, etc.

Our printing system covers the rest – the product name, nutritional information, allergen and ingredient lists, date coding, EST code, barcode, and everything else that is SKU-specific.

And our high-resolution printers produce excellent print quality that is virtually indistinguishable from your preprinted text on the package.

Because our thermal transfer printing systems are designed for the harsh conditions encountered in the protein packaging industry, they can be provided in environmental enclosures, protecting them from damp conditions. The printers can also be mounted in a cart that allows them to be moved away from washdown areas when the sanitation process occurs.

The result is reliable operation, even in the toughest conditions.

We offer two types of thermal transfer printing systems:

- Our Greydon system traverses across the web and is typically used on thermoforming or horizontal form fill seal machines.

- Our ID Technology fixed position thermal printers (TTO), often used on bagging, pouching and other types of flexible packaging machines

Note that on thermoforming HFFS machines, we can set out printers to print on the top web, the forming web, or both, allowing for maximum flexibility in your production operations.

Greydon TPM Series Printer

Greydon’s TPM Series of traversing thermal transfer printers are designed to integrate with horizontal packaging machines. They print during the dwell part of the cycle, traveling across the web and printing multiple packages in each traverse.

The TPM printer can be configured with 4-inch or 5 inches wide printheads, allowing printing of large formats – ideal for nutrition information, ingredient/allergy lists, UPC and 2D barcodes, and more.

For packages with a short index length, Greydon’s innovative split-platen design can allow for additional packages to be printed with each printer operation – increasing the throughput of the packaging system.

The TPM printers are controlled from a new color touchscreen interface – making it easy for the operators on the line. The interface can be installed in an IP65 enclosure for environmental protection.

ID Technology TTO Printers

Our TTO printers are designed to be integrated with many types of packaging equipment and include versions with print widths of 1.25 inches, 2 inches, and 5 inches.

They are ideal for printing onto packaging films and foils.

All models can print in either intermittent (while the film is stationary) or continuous (while the film is feeding) modes, making them highly flexible.

While the two smaller versions are excellent solutions for adding variable print to packages, the 5-inch printer can print nutritional panels, ingredient lists, allergen warnings, and more.

The ID Technology TTO printers are often found on vertical bagging machines, either singly or as a pair – one printer printing the front of the bag and one printing the rear.

As with the Greydon traversing printers, the ID Technology TTOs can be installed with environment cabinets, making them suitable for washdown areas.

The TTO printers can be controlled from an IP65-rated touchscreen, any connected web-enabled device or ID Technology’s Control apps, built on the NiceLabel platform.

Improve Your Protein Production with ProMach Labeling & Coding Solutions

By integrating our vast array of ProMach Labeling & Coding solutions in your protein operations, you get best-in-class printing and labeling systems, excellent support, and the opportunity to consolidate all the setup and data control into one integrated solution. That translates to greater throughput, increased efficiency, and a better bottom line.

To learn more about product coding and labeling for protein products, please contact us at IDT@ProMachBuilt.com .

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.