Code-A-Doodle-Do

Outstanding Product Coding Performance

In the meat/poultry industry, the variable print you add to your packages is very important.

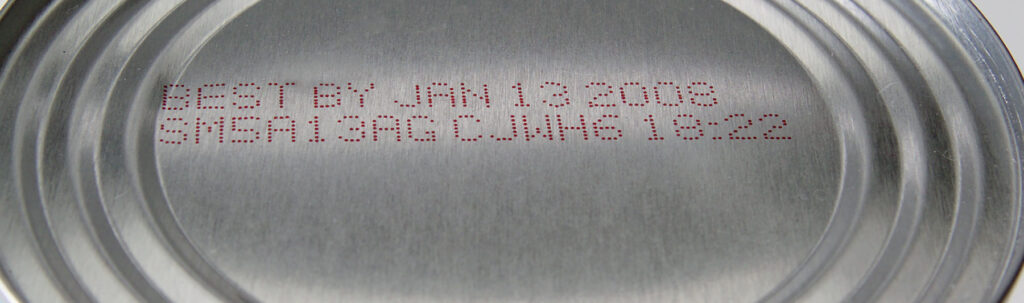

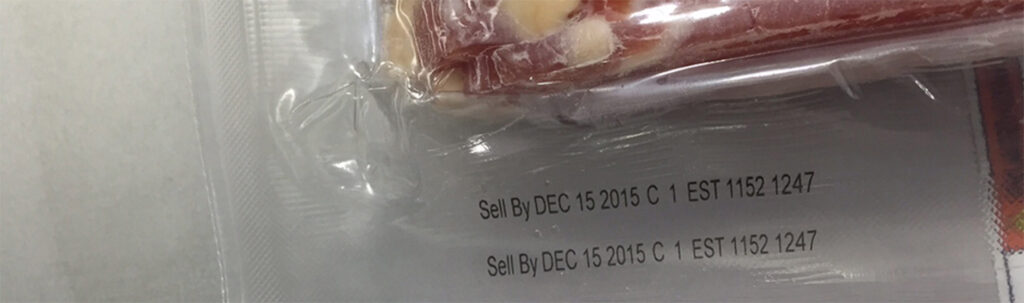

Date codes, lot codes, compliance logos, EST numbers, and (occasionally) barcodes must be printed on your package right at the point of packaging and be legible and accurate – every time.

Since these codes are usually printed on your primary packaging equipment, the printers must be tough enough to handle the cold and damp conditions in these areas of your packaging line.

Our portfolio of coding systems is carefully designed to address the issues that the protein industry faces: managing growth in a time of label shortages and dealing with an ever-increasing number of SKUs.

ProMach’s Labeling & Coding product brands – ID Technology, Greydon, and Code Tech – have decades of experience helping meat, poultry, and seafood customers improve the efficiency of their packaging lines by providing the best product coding technologies.

- Our solutions handle the challenging environments and demanding sanitation scenarios encountered in your industry.

- Understanding labor shortage challenges, our solutions are engineered to operate with minimal operator and maintenance intervention, allowing your team to support other aspects of your operations.

- We have vast experience in integrating coding systems into OEM packaging equipment, including innovative mounting hardware that ensures the printers are easily accessible for operators and the maintenance team.

- Many of our solutions allow replenishment of consumables while the equipment is running, reducing (or eliminating) downtime and improving your OEE.

- Systems can be controlled via ID Technology Control apps – built on the NiceLabel platform – to manage all your coding and printing data. This solution radically reduces the possibility of human error when setting up coding equipment.

- If you need technical support, our network of regional technicians are experts in all aspects of product coding for the protein industry, so you can be sure your team is trained correctly during installation.

Coding Technologies from ProMach Labeling & Coding

Continuous Inkjet (CIJ)

CIJ printers are the most common way to add variable information to packaging in many industries, including protein processing.

The printers run continuously, producing a jet of tiny ink droplets that are deflected to build the print image as the product passes. When correctly cleaned and maintained, CIJ printers can produce a good quality print that dries quickly and is robust.

Because a CIJ printer needs to produce the jet of droplets continuously, the solvent in the ink evaporates over time, and a makeup fluid (or additive) needs to be added to keep the ink viscosity constant. This additive process takes place automatically and means the CIJ printer needs to be replenished with both ink and makeup fluid from time to time.

Our Citronix CIJ printer is engineered to be exceptionally simple to use and maintain – without the need for expensive service plans or core replacements found in some competitive CIJ printers.

Citronix printers are designed and built in the USA to IP55 standards (IP65 is optional), making them ideal for use in the protein industry.

Where multiple prints need to be produced across the web, the Citronix printhead can be used with our Greydon Traverse System that moved the printhead across the web, printing as it goes.

CIJ printers offer a low cost per print, but this is somewhat offset (especially when using older, legacy printers) by being more maintenance intensive than other technologies.

Thermal Inkjet (TIJ)

Thermal inkjet printers from ID Technology and Code Tech are often the preferred solution for protein-coding applications.

In recent years, thermal inkjet technology advances have allowed TIJ printers to be very competitive in coding on packaging films and labels.

The small size of TIJ printheads means that they can be installed in small spaces on OEM packaging machines, and they are often used on HFFS machines where there need to be multiple codes across the web.

When multiple codes need to be printed, it is possible to install several printheads or to use a Greydon Traverse System that indexes one or printheads across the web.

ID Technology and Code Tech TIJ printers can be supplied in washdown enclosures, making them a good solution for protein packaging lines. A wide range of models is available to suit particular applications.

TIJ print technology is higher resolution than CIJ, resulting in excellent print quality for text, compliance logos, and barcodes. TIJ printers are particularly well suited for printing Datamatrix and QR Codes onto labels and flexible packaging.

Reducing maintenance and simple operation are vital attributes when considering using thermal inkjet technology.

While the cost per print can be a little higher than CIJ printing, the fact that maintenance and downtime can be radically reduced often makes TIJ the most cost-effective solution.

Thermal Transfer

Thermal Transfer Overprinters (TTO) from ID Technology and Greydon are engineered with protein packaging applications in mind. This solution uses a thermal ribbon (a similar process to tabletop thermal transfer printers) to transfer the image onto the package.

Because of our decades of experience integrating thermal transfer printers, these systems can be installed into any OEM packaging machine. The mounting hardware is designed to allow easy access for ribbon roll changes and routine maintenance.

TTO printers can be configured in 1.25 inches, 2 inches, 4 inches, and 5-inch print width versions to produce excellent print quality – approaching the quality of the pre-printed text on the package.

Greydon’s TPM Series of traversing thermal transfer printers are designed to integrate with horizontal packaging machines – printing during the dwell part of the cycle, traveling across the web, and printing multiple packages in each traverse.

Our TPM printer can be configured with 4-inch or 5 inches wide printheads, allowing printing of large formats – ideal for nutrition information, ingredient/allergy lists, UPC and 2D barcodes, and more.

ID Technology TTO printers are designed to be integrated with many types of packaging and labeling equipment and include versions with print widths of 1.25 inches, 2 inches, and 5 inches. These are ideal for printing onto packaging films, foils, and pressure-sensitive labels.

While the two smaller versions are excellent solutions for adding variable print to packages, the 5-inch printer can print nutritional panels, ingredient lists, allergen warnings, and much more.

All models can print in either intermittent (while the film is stationary) or continuous (while the film is feeding) modes, making them highly flexible.

Our TTO printers can be provided with washdown enclosures for use in harsh environments, or also can be built into carts to allow the complete assembly to be quickly removed from packaging areas when the sanitation process occurs.

Improve Your Protein Production with ProMach Labeling & Coding Solutions

By integrating our vast array of ProMach Labeling & Coding solutions in your protein operations, you get best-in-class printing and labeling systems, excellent support, and the opportunity to consolidate all the setup and data control into one integrated solution. That translates to greater throughput, increased efficiency, and a better bottom line.

To learn more about product coding and labeling for protein products, please contact us at IDT@ProMachBuilt.com .

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.