Panther Shipping Labeling Automation Solutions.

If you need to integrate systems into a distribution center, fulfillment center, or e-commerce operation, one of the final pieces is shipping picked orders out to the happy customer.

At Panther, we have shipping labeling automation solutions designed to interface with your management system that help make this crucial part of the process as simple and efficient as possible.

Shipping Label Processes

Depending on the operation’s needs, shipping label processes can range from simple manual operations to fully integrated high-speed automatic systems.

The shipping label – which is formatted to use the appropriate freight or parcel system – is usually applied to the top of the package.

Manual Shipping Label Process

In the simplest form, once the order has been picked, packed, and the package sealed, the operator produces a shipping label on a desktop or tabletop printer right at that location.

Usually, the label printer will be connected to the shipping system of the delivery company being used – FedEx, UPS, etc., which allows the operator to choose the correct details for printing on the label.

While this method can be very effective for low-volume operations, a level of automation makes sense for higher-volume facilities.

Automated Shipping Label Process

When the shipping label process is automated, the labeling usually takes place some distance from where the package was packed and sealed.

This means that a method must be employed to accurately identify the package and link it to the correct order to ensure it receives a shipping label that contains all the right customer information.

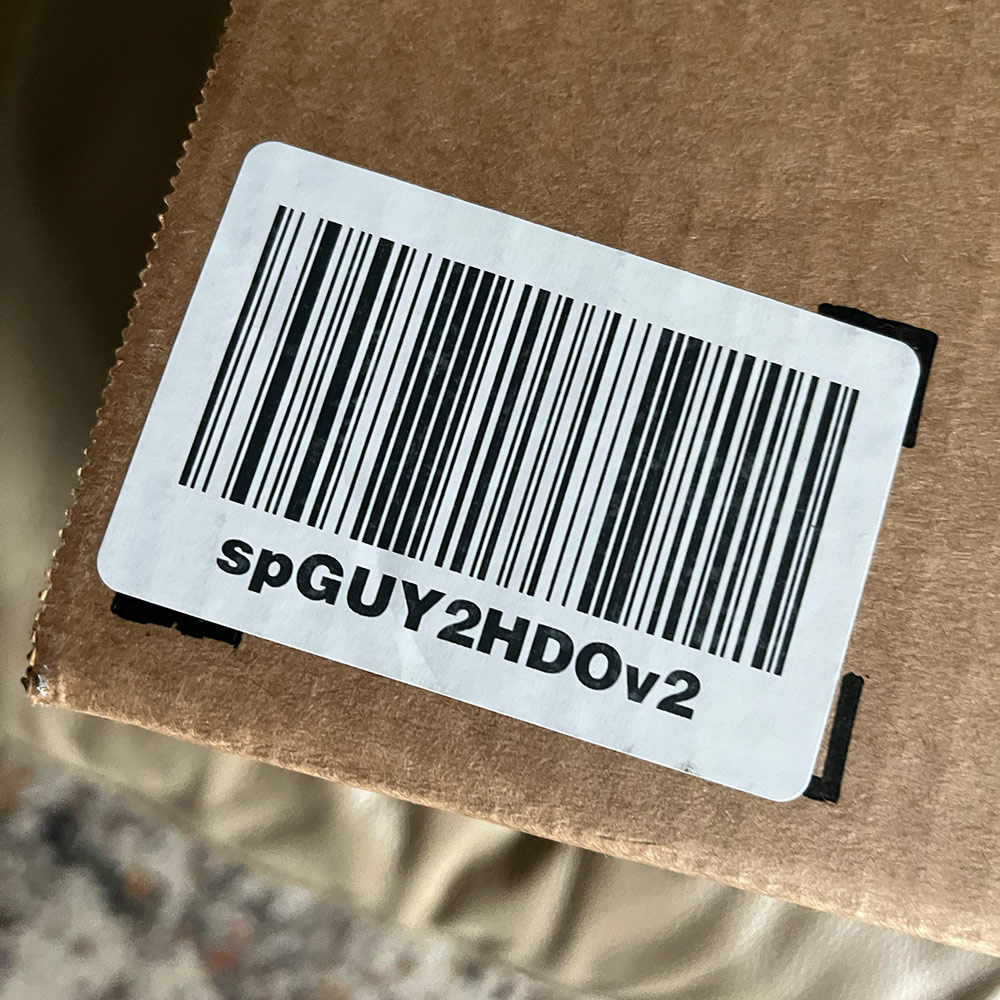

This is usually achieved by having a license plate barcode (LPN) attached to the package as picking for the order is completed.

When the order is successfully picked, the operator places the LPN label (Amazon calls their version of this an SP00 label) on the package and scans it with a barcode scanner to associate the license plate number (and hence the package) with the customer’s order in the database.

Many logistics systems for fulfillment and e-commerce use the SLAM (Scan – Label – Apply – Manifest) concept that is often associated with Amazon’s fulfillment center operations. This is well-proven as being an excellent solution for busy shipping areas.

Scan

In the first stage of the SLAM process, the package is scanned.

Depending on the application, the scanning operation can consist of simple barcode scanning of the LPN barcode or an extensive scan tunnel system that scans the barcode and measures all the dimensions of the package.

The scan station also often includes a weigh scale to determine the weight of the package.

All the data collected is uploaded to the management system, where it is merged with all the customer orders and product information.

The management system then sends to the print and apply labeling machine all the information that needs to be printed for that particular shipping label as well as the height information of the package.

Label

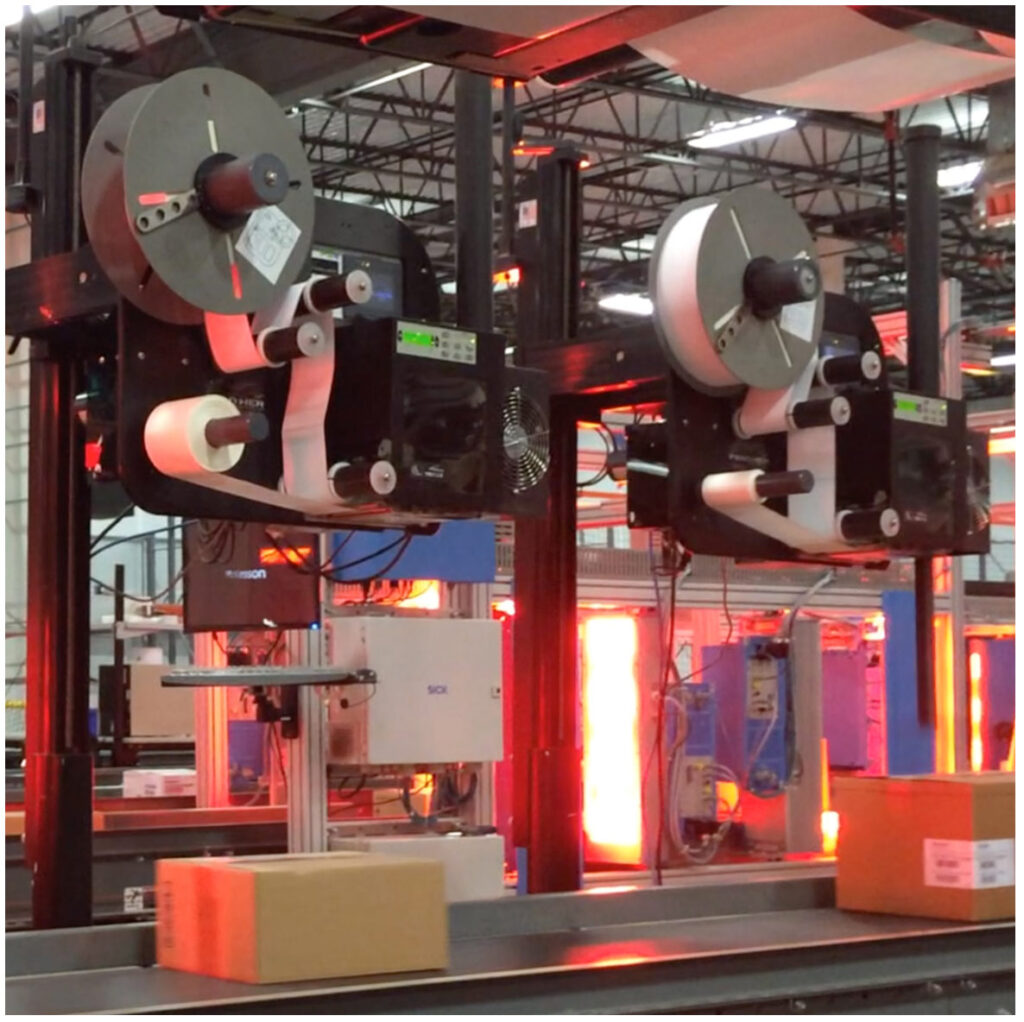

As the package arrives at the labeling station, the automatic labeling system is able to print the correct shipping label using the customer address and package info provided by the host system.

Apply

In the apply stage, using the package height information from the host system, the labeler gently applies the shipping label to the top of the package in the correct location.

Manifest

In this final stage, the barcode on the LPN barcode is scanned, along with the barcodes on the shipping label, to ensure everything matches.

If everything is good, the package proceeds to be shipped.

Should any of the codes not match, the package is diverted for inspection and possible re-work.

The final data is also written back to the order record – allowing the customer to view the status of their package and get their shipping and tracking information.

Panther Systems for Shipping Labeling Automation

At Panther, we specialize in labeling automation systems for use in logistics facilities, such as distribution centers, fulfillment centers, and e-commerce operations. Our products are mainly sold via material handling and warehouse integrators.

Our flagship labeling system, the Predator, is used in many of the most demanding locations.

Designed to print and apply shipping labels to the top of mixed products as they go from packaging to shipping, Predator’s servo-controlled tamp applicator can handle products from a couple of inches high to up to 58 inches, allowing it to cope with even radical height variations from one package to the next.

The Predator is all-electric in operation, needing no plant air to operate, and the machines are engineered to interface with a host system to create a fully integrated shipping labeling automation solution.

Label and Pack Slip Automation

In some applications, there is a need to supply a pack slip along with the shipping label.

Panther offers two techniques to address this need.

Label Over Label – Tandem

In this case, a pair of print and apply labelers (usually Predators) are installed in tandem. When a package needs to be labeled, the pack slip data is sent to the first machine and the shipping label information to the second.

The pack slip is applied first and the shipping label afterward by the second machine.

Both the shipping label and the packing slip are perforated and removable so that they can easily be removed from the package by the recipient.

The advantage of this tandem machine approach to label and pack slip automation is speed. The output achieved is usually the same as printing and applying a single 4 x 6 inch shipping label to the package.

NEXTStep

Panther’s NEXTStep concept is an alternative to using two labeling systems in tandem to print and apply the shipping label and pack slip to the package.

In this case, the label and pack slip are printed on a single, custom-designed label that is printed and applied on a single print/apply machine.

When the combined label and pack slip has been printed and positioned on the applicator tamp pad, it is folded over prior to application to the package.

Because of the longer length of material to be printed and the time needed to produce the folded item, NEXTStep is not able to reach the same output speeds as the tandem label-on-label method.

For low-volume applications, Panther can also provide a semi-automatic NEXTStep solution.

The combined shipping label and packing slip is printed on a tabletop barcode printer, folded, and presented to the operator, who then manually applies it to the package.

As with the tandem label-on-label solution, the NEXTStep labels are perforated and designed to be easy for the package recipient to remove the shipping label to get access to the packing slip.

Why Panther?

At Panther, we understand the importance of labeling for our integrators and end users.

We have worked hard to become the number one brand integrators to turn to when needing labeling equipment for their projects. Many of the largest integrators in the industry and many smaller groups specify Panther as their go-to labeling partner.

As well as providing excellent hardware for logistics labeling applications, Panther also offers excellent support both before the sale and to help keep your equipment running perfectly.

As part of ProMach Labeling & Coding, Panther has an extensive nationwide support network and also, access to high-quality ID Technology labels for both direct thermal and thermal transfer printing.

If you are an integrator of labeling systems into logistics operations such as e-commerce, fulfillment centers, and distribution centers, Panther is uniquely organized to help make the labeling part of your project simple.

Want to learn more about how Panther can help with your logistics labeling operations? Contact us at Panther.Sales@ProMachBuilt.com or visit us online to get started!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.