Laser Coding for Wineries

We do indeed pair well with wine – especially our Macsa laser coders.

If you work in the wine industry, you’re probably already aware of some of the advantages of using well-proven lasers for adding production and traceability codes to your bottles.

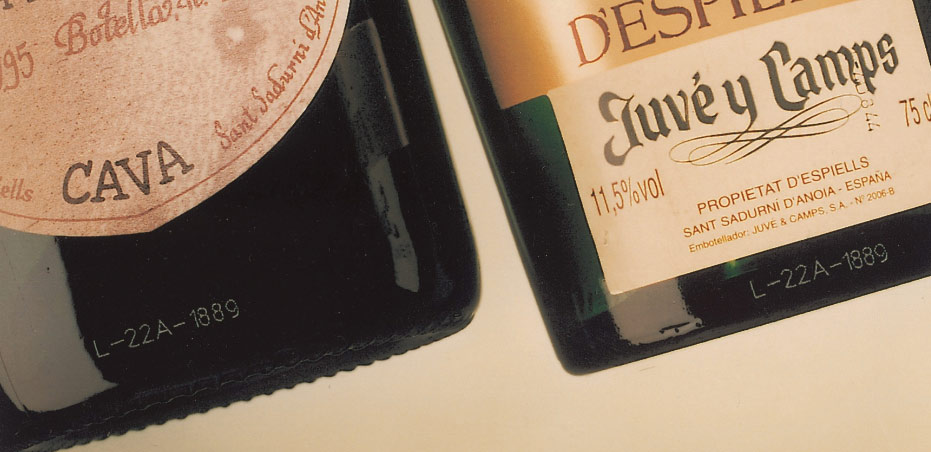

High-Quality Permanent Markings – Codes right on your glass bottles without worrying about being removed or washed off. This is important for maintaining traceability, especially for high-value wines.

Environmentally Friendly – Laser coders don’t use inks or solvents that can be harmful to the environment, and there is no need to have to manage the disposal of hazardous materials.

Minimal Maintenance Requirements – No complex cleaning and core changing routines that are associated with legacy inkjet printers. Resulting in greater uptime, better OEE, and ROI.

Low Operating Costs – No additional consumables needed to be purchased, improving the return on your investment and saving on space and handling.

Coding & Marking Other Packaging Materials

While adding codes to your bottles is probably the first application that comes to mind, lasers can also help with some other printing jobs in your organization.

Do you package your wine in alternative materials such as PET bottles or TetraPak packages for single servings? Our Macsa lasers are ideal for these applications as well – providing high-quality coding without the need for costly consumables.

Prefer your production codes to be printed on the label? No problem, lasers can do that too.

Custom Printed Barrels

Whether you need unique markings on barrels for special reserves, new prestige product offerings, or overall branding consistency, our HPD model lasers provide an exciting alternative to traditional decorating techniques.

Using a laser with a large imaging field allows for the ends of barrels to be printed in-house and on-demand and customized when needed.

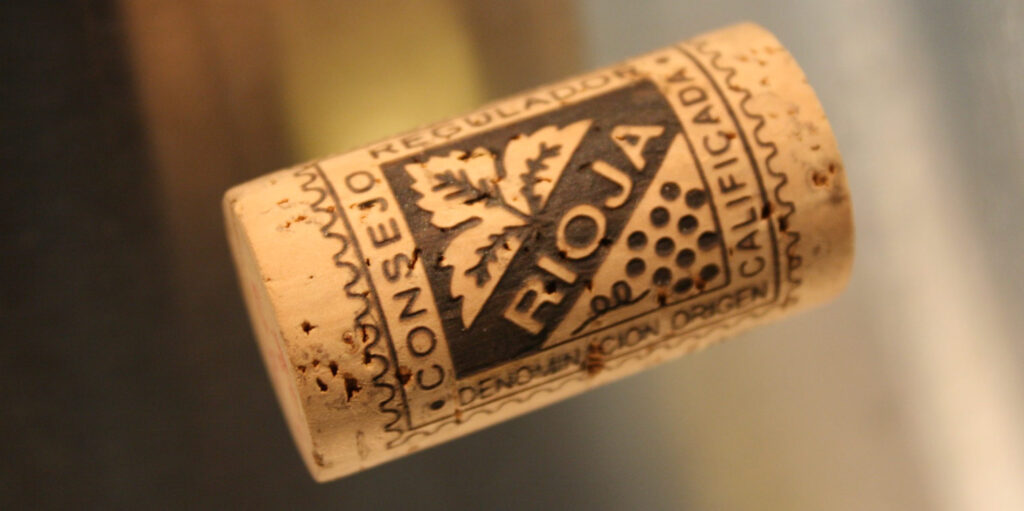

Printing Corks

Traditionally, printing on corks for wine bottles was done using either pad printing or thermo-etching. Because both of these techniques incorporate the use of engraved plates, they are not always the best for short production runs.

Macsa lasers can help with this by printing directly onto the cork material, utilizing an all-digital workflow.

Other Ways ID Technology Can Help

As well as the laser coding solutions, ID Technology also provides product labeling equipment, print/apply labeling systems for shipping cases and pallets, high-quality labels, and more.

Contact us at IDT@ProMachBuilt.com or call 817-626-7779 to learn more about our solutions.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.