If you work in a warehouse or any kind of fulfillment center, or your company integrates systems into these locations, you’ll know how important it is to be able to keep track of every item that arrives at your receiving dock.

Goods can arrive at your dock in various forms. They may be palletized, each pallet containing one single SKU; it could be mixed pallets. Then again, many goods arrive un-palletized. They can be in loose corrugated boxes of various sizes.

How best to handle these, and ensure they can be completely and accurately tracked through your system, is crucial to efficient operation.

License plate labeling is perhaps the simplest and most efficient means of identifying these inbound items using a unique license plate barcode label for each one.

Like the familiar license plate on automobiles, the license plate barcode on the package is the key to looking up all the information on that particular item stored in the WMS database.

How the Process Works.

When random size items are unloaded at the receiving top, they are usually placed onto a conveyor where the first step is to identify what the package is, what it contains, and its dimensions.

This information is provided to the Warehouse Management System (WMS), which will determine where that package needs to be put away in the warehouse until it is needed for up order later.

The license plate barcode is placed on the package at the inbound labeling station. It is scanned with a barcode scanner, and the license plate number is stored with the rest of the item data in the WMS system.

Once this is complete, the WMS system will determine where that package needs to be put away in the warehouse until it is needed.

In small or low-volume operations, the license plate barcode labels are often applied by hand. It is, however, very common to automate this process, especially in larger, busy warehouses, distribution centers, and e-commerce facilities.

Labeling Systems that Enable this Process.

At Panther, we specialize in labeling automation solutions specifically for logistics applications such as license plate labeling.

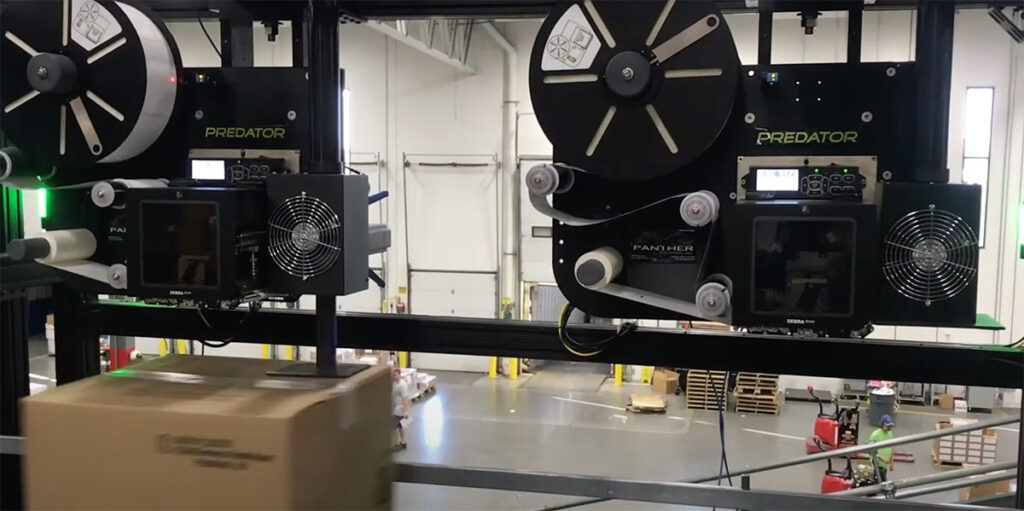

For example, Panther’s Predator print and apply labeling system is a market leader in the application of applying license plate barcode labels for inbound and receiving operations.

A Predator labeler is normally installed in the conveyor system immediately after the package dimensioning system.

The barcode label is printed and applied right at the time of use, in many cases using package height information provided by the host WMS system.

For very high volume operations, a pair of predator labelers is often used in tandem, each one labeling every other package.

The predator is perfect for applying labels to the top face of random-sized products. Its servo-powered electric tamp applicator uses no compressed air and can gently label varying-size items up to 58 inches high.

Once the label has been printed and applied, a barcode scanner reads the data encoded in the barcode and then adds this to the rest of the data for that package in the WMS system.

Why Panther?

At Panther, we understand the importance of labeling for our integrators and end users.

We have worked hard to become the number one brand integrators turn to when needing labeling equipment for their projects. Many of the largest integrators in the industry and many smaller groups specify Panther as their go-to labeling partner.

As well as providing excellent hardware for logistics labeling applications, Panther also offers excellent support both before the sale and to help keep your equipment running perfectly.

As part of ProMach Labeling & Coding, Panther has an extensive nationwide support network and also, access to high-quality ID Technology labels for both direct thermal and thermal transfer printing.

If you are an integrator of labeling systems into logistics operations such as e-commerce, fulfillment centers, and distribution centers, Panther is uniquely organized to help make the labeling part of your project simple.

Want to learn more about how Panther can help with your logistics labeling operations? Contact us at Panther.Sales@ProMachBuilt.com or visit us online to get started!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.