If your company produces baked goods, muffins, croissants, cupcakes, etc., you might well package them for retail in clamshell-type containers.

The ideal way to label this kind of package is often with a c-wrap label, which has several advantages:

C-wrap labeling uses a single label visible on the top of the package, wraps around the side, and effectively labels the bottom of the containers well.

The label section on the top of the package carries the branding and marketing message, while the part on the bottom is where the ingredients, nutrition information, and allergen statements are printed.

A crucial part of the c-wrap label concept is providing security and tamper evidence for the package.

The label prevents the package from opening when being handled during shipment or in the retail store. It also means the package can’t be opened or tampered with unless the label is torn – an important security feature.

Applying C-Wrap Labels

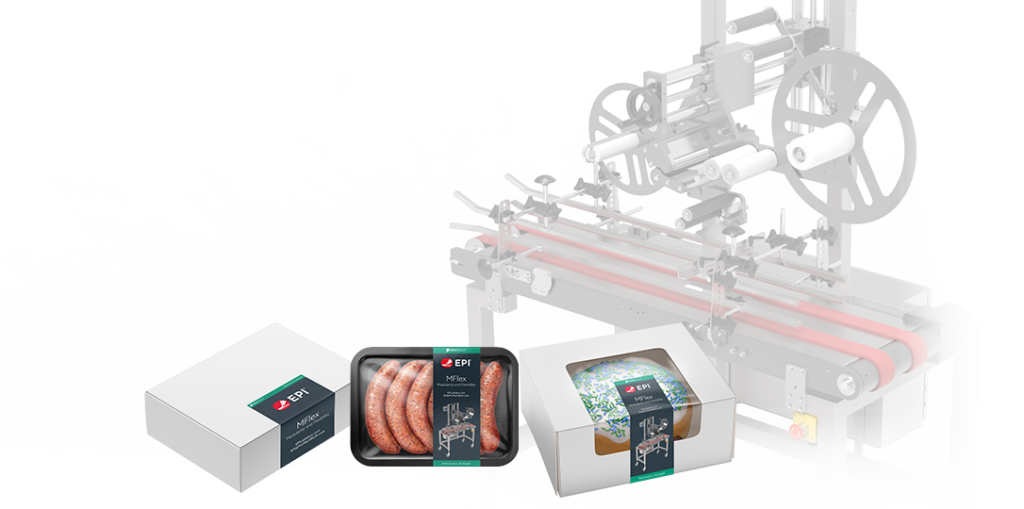

The MFlex™ labeling system from EPI is engineered to efficiently handle many types of labeling applications, including applying c-wrap labels.

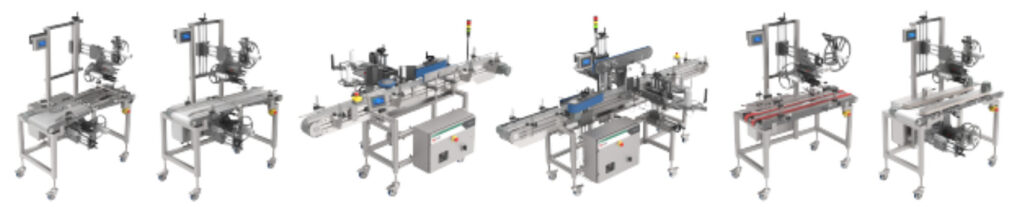

There are, in total, three MFlex configurations that can apply c-wrap labels to your product.

A dedicated c-wrap machine that is optimized for this application.

A versatile MFlex can be set to apply c-wrap labels and a label to the package’s top or bottom (or both). This is ideal for customers such as co-packers that need maximum flexibility.

Finally, MFlex can be configured with a hugger-style side grip belt assembly for containers that might be challenging to label using a conventional conveyor.

The MFlex Concept

The MFlex line features an innovative label applicator and integrated product handling solution that supports a wide range of product and package labeling applications by simply choosing modules from our extensive portfolio. But that is only the start of this simple yet sophisticated labeling solution.

Our full range of modular label applicator configurations makes the MFlex perfect for almost any type of product or package labeling your production requires. This flexibility also supports our singular design philosophy – system components are common across the entire suite of options, making routine service and support very efficient and straightforward.

One Control to Rule Them All

Have you noticed that some labeling systems have multiple control interfaces, some quite complicated?

We want the operators to love the MFlex, so each labeler has a singular HMI from which the entire machine is controlled—without having to move to a different part of the system to adjust or change settings.

The system is designed to be simple for routine tasks but can also help maintenance with in-depth diagnostics when needed.

Want to reduce set-up time? It’s easy; once you have a labeling job set up and ready to run, save it as a recipe, ready to instantly recall for next time.

Syncing Outside the Box

Synchronizing all the machine modules on a labeling machine is critical to getting the best results. That’s why we’ve made MFlex amazingly intelligent with its closed-loop servo drive system.

The speeds of the labeler modules are monitored constantly and the system responds to any changes in real-time.

If the conveyor speed changes while the machine is applying a label – or even stops completely – the label is still correctly positioned on the product every time.

This sophisticated system works happily behind the scenes, ensuring everything is in perfect sync while the operators can get on with other tasks.

Harsh Environment? Bring it on!

Packaging equipment doesn’t always have the luxury of operating in perfect conditions. Sometimes, the areas where machines such as labelers are installed are wet or dusty, or the equipment has to be washed down for sanitation.

That’s why we engineered our MFlex machines to meet IP65 protection standards right out of the box. No need to pay extra or to specify optional features. Every MFlex is built on the understanding that it might have to work in less than perfect conditions.

Even if your packaging line is set up in a friendly environment, having your labeler designed to this standard will help prolong its service life.

Simple, Yet Sophisticated

By engineering, MFlex to be simple to use and maintain, and building in the latest in sophisticated motion control technology, MFlex is the perfect solution for many labeling applications.

If you want to learn more about the MFlex for c-wrap or any other configurations, just contact us at EPI@ProMachBuilt.com; we’d love to help!

You can also download the spec sheet on the MFlex C-Wrap right here!

Labels for Your C-Wrap Labeling Applications

While we’re here, it’s a good time to mention ID Technology labels.

EPI customers can enhance their labeling operations by running ID Technology labels on their MFlex labeling equipment.

With 10 label production plants across North America and major investments in technology and people, ID Technology is the national supplier with local support.

Flexo and digitally printed labels are available as well as thermal labels for your secondary packaging – we even offer special warranty deals for customers using our labels and equipment.

The perfect solution for your c-wrap labeling and other labeling applications.

Check out our label products here: ID Technology labels.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.