When you are looking to acquire a pressure-sensitive labeler for round containers, there are quite a lot to consider.

There are many to choose from at all price points, from low-cost semi-automatic machines to high-speed rotary labelers.

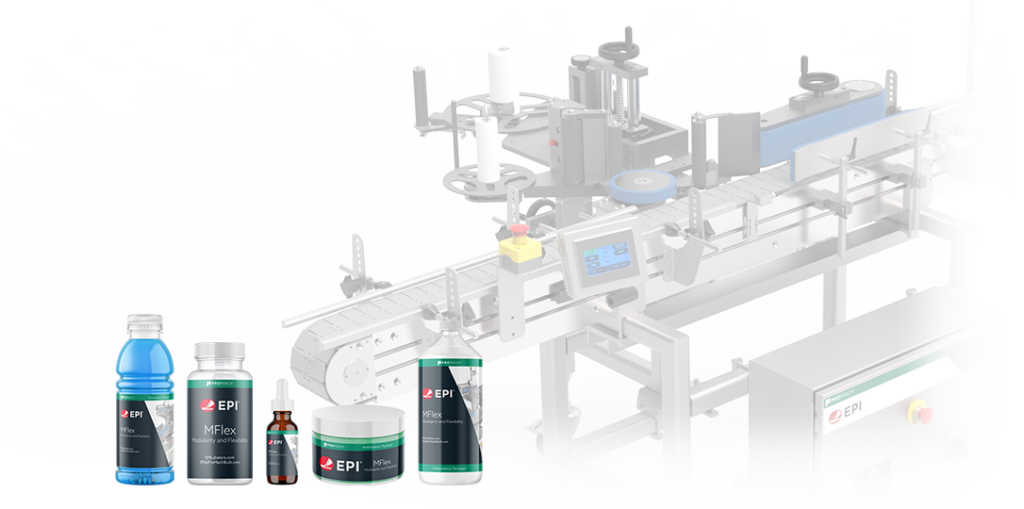

To help make things easier, we’ve introduced the EPI MFlex™ Wrap – our new labeling system engineered to make things simple for your operators and maintenance team while also being sophisticated enough to handle a large range of labeling operations.

MFlex is a portfolio of modular pressure-sensitive labelers, sharing many common features, but configured and perfected for each role.

With our MFlex Wrap labeler, we have thought through all the important details, so you don’t have to worry about them.

As well as an integrated mechanical design and the ability to accurately label a wide range of round container sizes, MFlex Wrap has some special features that set it apart from the rest.

One Control to Rule Them All

Have you noticed that some labeling systems have multiple control interfaces, some quite complicated?

We want the operators to love the MFlex, so each labeler has a singular HMI from which the entire machine is controlled—without having to move to a different part of the system to adjust or change settings.

The system is designed to be simple for routine tasks but can also help maintenance with in-depth diagnostics when needed.

Want to reduce set-up time? It’s easy; once you have a labeling job set up and ready to run, save it as a recipe, ready to instantly recall for next time.

Syncing Outside the Box

Synchronizing all the machine modules on a labeling machine is critical to getting the best results. That’s why we’ve made MFlex amazingly intelligent with its closed-loop servo drive system.

The speeds of the labeler modules are monitored constantly and the system responds to any changes in real-time.

If the conveyor speed changes while the machine is applying a label – or even stops completely – the label is still correctly positioned on the product every time.

This sophisticated system works happily behind the scenes, ensuring everything is in perfect sync while the operators can get on with other tasks.

Harsh Environment? Bring it on!

A lot of packaging equipment doesn’t have the luxury of operating in perfect conditions – sometimes the areas where machines such as labelers are installed are wet or dusty – maybe the equipment has to be washed down for sanitation.

That’s why we engineered our MFlex machines to meet IP65 protection standards right out of the box. No need to pay extra or to specify optional features. Every MFlex is built on the understanding that it might have to work in less than perfect conditions.

Even if your packaging line is set up in a friendly environment, having your labeler designed to this standard will help prolong its service life.

What Options are Available for MFlex Wrap?

In its basic form, the MFlex labeler for round containers consists of welded stainless steel frame, conveyor section, product spacing wheel, an M2 system labeling head, and a label wrap station.

This configuration can handle many labeling applications, but there are optional modules that can make it even more flexible:

- Twin belt product spacing device

- Vacuum wrap station for long or curved labels

- Trap and spin module for unstable containers and ally a label in register

- Integrated TTO, laser or thermal inkjet coder for adding variable information to labels

- Zero-downtime solutions

Do you need to label oval or flat containers as well as round? You should look at our versatile MFlex Front, Back & Wrap labeler for maximum flexibility.

Simple, Yet Sophisticated

By engineering MFlex to be simple to use and maintain and using the latest in sophisticated motion control technology, MFlex is the perfect solution for many labeling applications.

If you want to learn more about the MFlex Wrap or any other configurations, just contact us at EPI@ProMachBuilt.com; we’d love to help!

You can also download the spec sheet on the MFlex Wrap right here!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.