What is air assist?

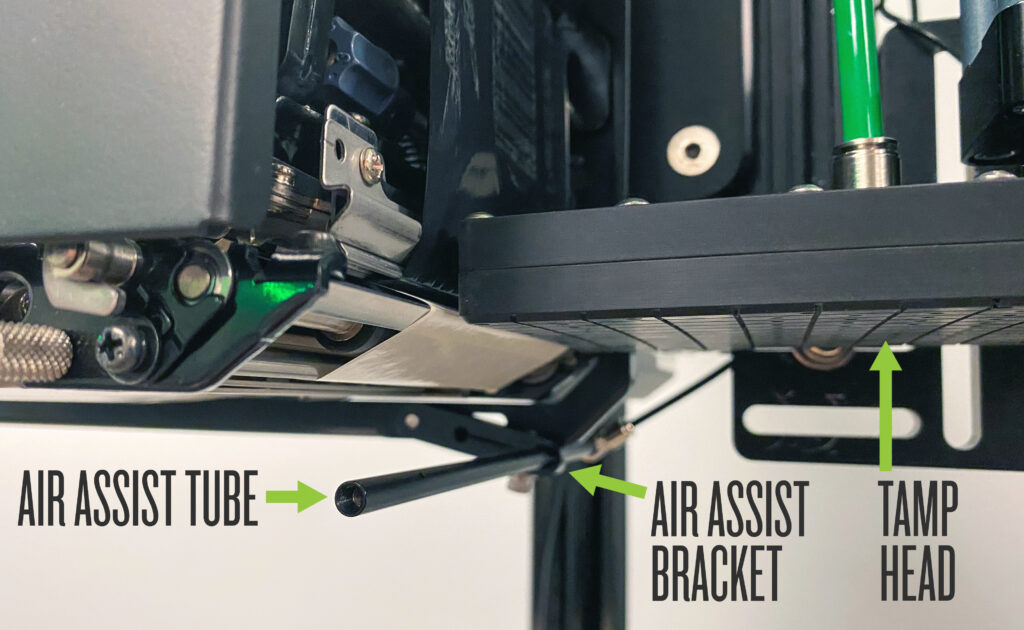

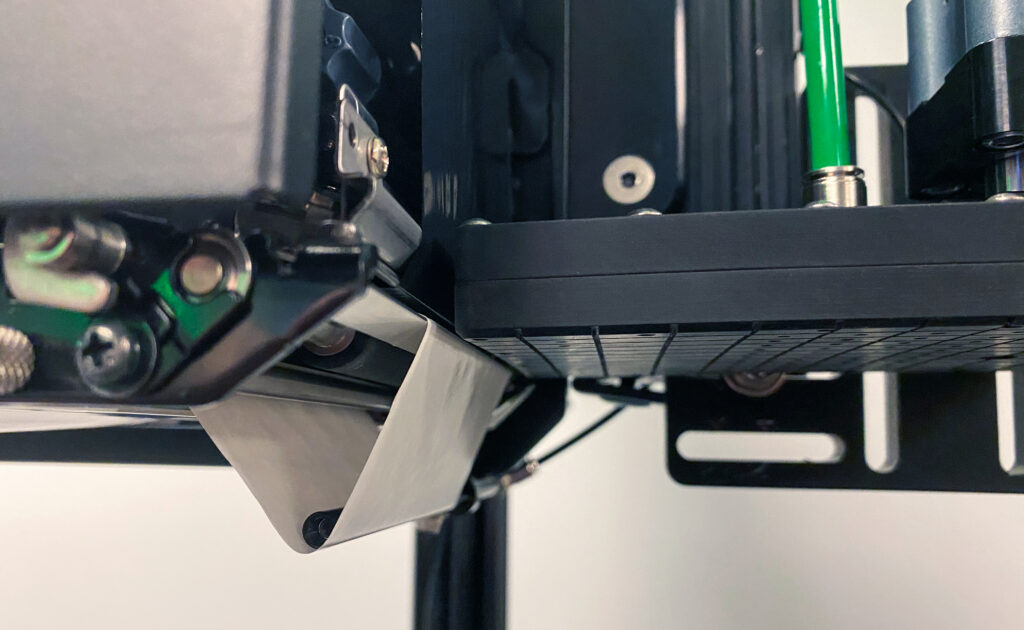

Generally speaking, the air assist component helps a label stay flat as it feeds across the tamp head. The air assist mechanism is comprised of an adjustable bracket that holds a tube containing three very small holes that blows air onto the underside of the label. This feature comes standard on pneumatic printer applicators such as the Phantom Printer Applicator, as well as pre-printed pneumatic labeling systems.

Why is an air assist important?

Without it, a label would not feed flat onto the tamp head, preventing the vacuum from holding the label prior to application.

They can be challenging to adjust because they are positioned differently based on the size of label you are using for your application. One approach doesn’t fit all, but we utilize standard practices to follow that provide a good starting point and process to get you where you need to be for your specific system.

What is required for the correct setup of an air assist?

Generally, an operator should pay attention to the position of the air tube, both in terms of distance from the platen roller and the angle the air is blowing onto the underside of the label. As there can be various label lengths and customer requirements, there is some fine tuning required to “dial-in” an air assist and have it perform optimally for each specific system.

If the air assist tube is blowing air at too steep of an angle, the air from the holes creates drag on the label and causes it to flutter or ripple onto the tamp head. If the air assist tube is blowing air at too shallow of an angle, the label is pushed too far forward or completely off of the tamp head.

Is an air assist present on all Panther Industries systems?

The air assist is standard on every pneumatic system. The tamp head of a pneumatic system has a pattern of shallow channels that, coupled with airflow driven by a vacuum generator, helps the label to remain on the tamp head until it is applied. The air assist keeps the label flat as it travels across these channels so the vacuum can properly “grab” and hold the label prior to application.

The air assist is also present on our Predator Printer Applicator that features the NEXTStep Applicator (shown below). The label – comprised of both a shipping label and pack slip – is 12” long and feeds across two heads (a fold head and a tamp head) prior to being folded and applied. So the additional assistance to keep the longer label flat as it travels across those two heads is critical.

What types of support do end-users typically require related to the air assist function?

There are three primary types of support issues we hear related to the air assist function.

The first type is an issue where something has collided with the air assist components (the bracket and tube sit lower than any other portion of the labeling automation system) and the labels no longer feed correctly onto the tamp head. If only the mounting bracket is affected, a simple adjustment to the bracket and angle of the air holes should solve the issue. If the tube is damaged or bent, a replacement air assist tube will need to be installed.

A number of our partners and end-users purchase additional air assist tubes to have on hand for this exact scenario. One is included in our spare parts kit, and individual tubes can be ordered separately through our parts department at Panther.Parts@ProMachBuilt.com.

The second type of support issue we hear from end-users is “the vacuum doesn’t work” because the labels are not remaining on the tamp head. More often than not, this issue is related to the air assist components and not the vacuum itself. If the air assist tube is not damaged or bent, an adjustment to the mounting bracket and air assist tube angle solves the issue.

A third issue we see with the air assist tube is due to the label liner being incorrectly routed over and around the tube, blocking and preventing it from blowing any air onto the label as it is presented to the tamp head (shown below). Even after correcting a label liner routing error, the position of the air assist tube may have been inadvertently adjusted, causing other issues. So it is important to follow the label routing diagram of each system and avoid covering the air assist tube.

What types of routine or preventative maintenance should be performed on the air assist components?

A good preventative maintenance practice is regular cleaning of the air assist tube (and holes) with isopropyl alcohol to remove any excess residue or debris that has built up on the tube. This ensures the air is flowing properly from the holes to the underside of the label.

In addition, as mentioned previously, purchasing a quantity of extra air assist tubes to have on hand in the event a replacement is needed demonstrates best practices and maximizes uptime.

Where else can a customer reference information on this topic?

Additional information on setup or maintenance of the air assist function can be referenced in the product manual for your specific system or on the dedicated air assist support page.

For any service or support-related issues related to your Panther print and apply labeling or pre-printed labeling automation systems, please contact us at Panther.Service@ProMachBuilt.com or toll-free at 800-530-6018, x120. To order parts, please contact us at Panther.Parts@ProMachBuilt.com or toll-free at 800-530-6018, x175

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.