Do you need to comply with the secondary packaging guidelines for labeling for Walmart?

This list of questions we are frequently asked might be helpful.

To learn more about GS1 standards, visit the GS1 website, or you can see our Introduction to GS1 Barcodes, here.

Does this apply to all products that are shipped to Walmart?

This FAQ covers the requirements of Walmart’s Secondary Packaging Supply Chain Standards, as published in January 2022.

This FAQ does apply to many classes of products, but almost certainly not everything. Therefore, we recommend discussing this with your Walmart representative to ensure you follow the correct guidelines for your particular products.

What kind of barcode needs to be printed on the package?

Currently, two types are used in the Walmart supply chain:

ITF-14 (also often referred to as GTIN-14) and GS1-128.

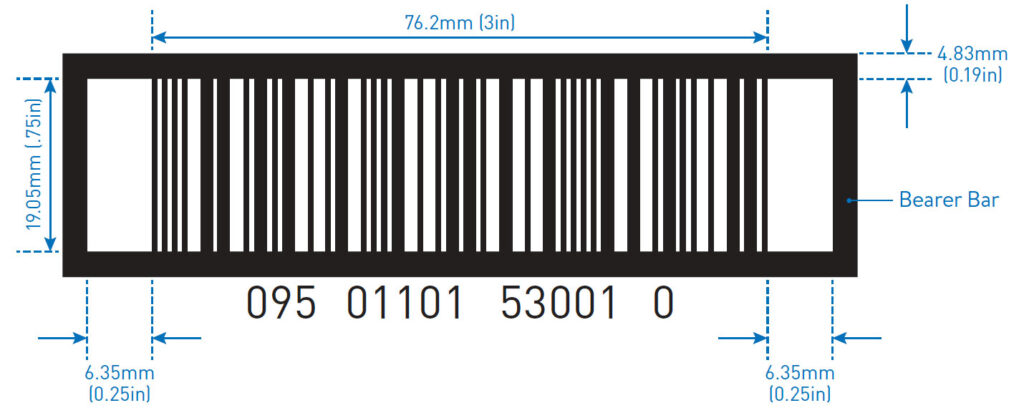

ITF-14 is the most widely used barcode in the supply chain. It always consists of 14 alpha characters representing the GTIN (Global Trade Item Number) assigned to that product configuration.

Note that the GTIN-14 used for secondary packaging is not the same as the UPC number for the actual product. Each product/package configuration needs to have its unique GTIN, and Walmart (correctly) points out that the first digit can be used to identify the level of packaging.

Note that the bearer bars (the black borders often seen around ITF barcodes) are optional for Walmart.

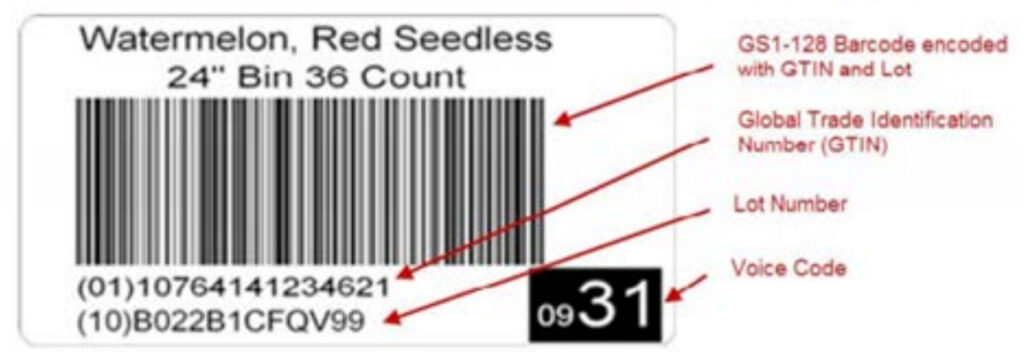

The other barcode symbology used in the Walmart supply chain is GS1-128.

GS1-128 is a much more versatile barcode and can contain a lot more data. Code 128 can encode all 128 characters in the ASCII character set (hence the name) and by using GS1 Application Identifiers, the GS1 version can include much more than just the GTIN.

For some products (such as fresh produce as well as meat/poultry) shipped to Walmart, GS1-128 is mandatory and will always have additional data encoded. An example is the Product Traceability Innitiative (PTI) label used for fresh produce.

For compliance with PTI, the label includes a GS1-128 barcode with Application Identifers 01 (GTIN) and 10 (Lot Number) encoded.

Does it need to be printed on a label, or are there other options?

Walmart does not specify how the barcode on the shipping case or tray is printed.

Because there is no variable information encoded in the barcode, the GTIN-14 data is often encoded in a pre-printed barcode printed to the case or tray at the corrugated converter.

It is also common to see the barcodes printed on labels or printed as part of the packaging process using inkjet printers or laser coders. While inkjet is being successfully used by many suppliers, Walmart does tend to discourage the use of this technology and use of inkjet should be confined to ITF-14 barcodes.

Where should the barcodes be located on each package?

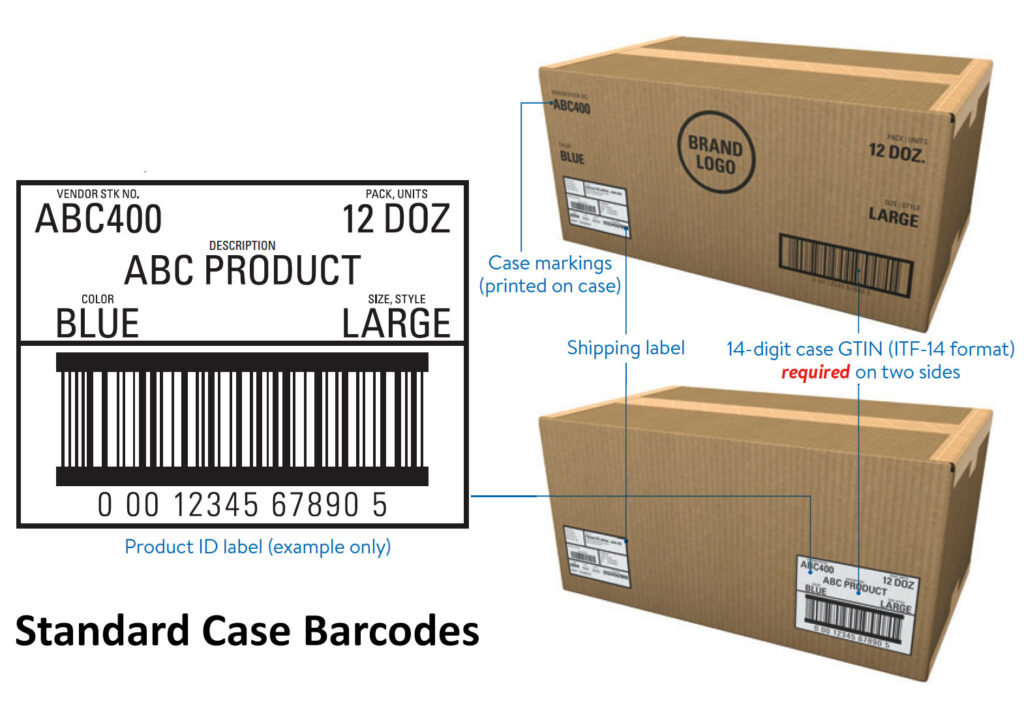

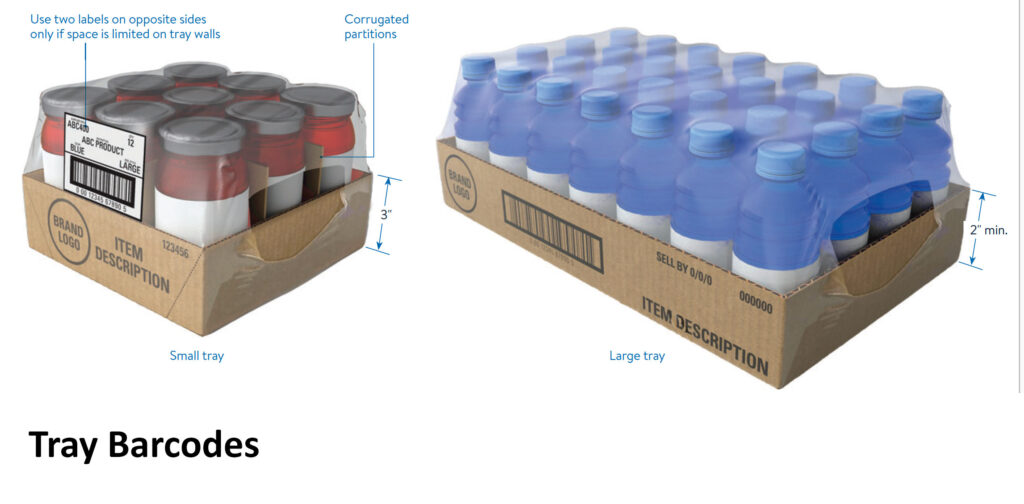

Walmart mandates that each case or tray has two barcodes, one must be on the longest side.

Walmart mandates the barcodes to be located on at least two sides of each case or tray and if the item is to be palletised, at least one barcode on each outside package needs to be visible when stacked on the pallet.

The height and location of each barcode needs to comply with the usual GS1 standards.

What about pallets?

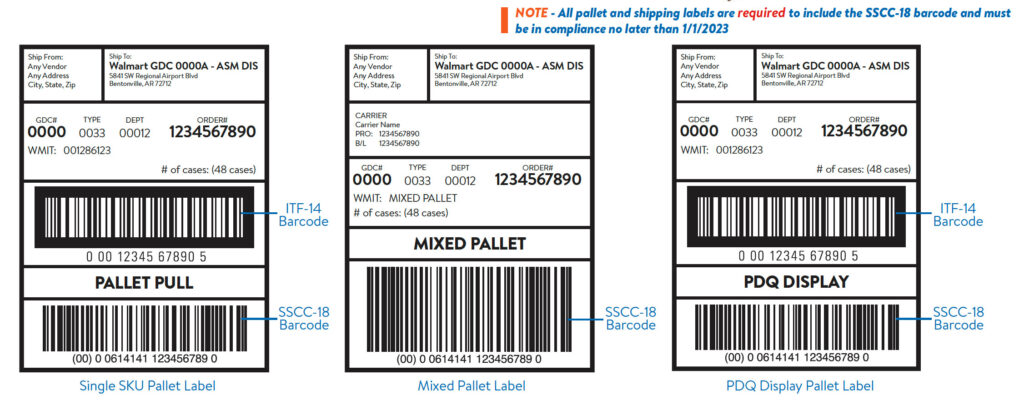

Barcodes on pallets are very important for traceability and Walmart requires to have GS1 compliant pallet labels – all supplier must be in compliance with this by the start of 2023.

These include an SSCC barcode (a version of GS1-128) that includes a unique serial number for each pallet that is shipped.

Walmart requires pallets to have SSCC labels on at least two sides of each pallet – ideally located in the top right-hand corner (Note that GS1 is more flexible with pallet label positions).

Does Walmart use GS1 standards?

Walmart states that barcodes need to be to GS1 standards, but there are some areas where Walmart’s rules and GS1 are not the same.

The first is in the definition of a GTIN-14. Unfortunately, how Walmart describes the construction of the GTIN-14 and its relationship with the UPC code of the item in the package is a little confusing.

The Walmart standard states that a company GS1 prefix is always five digits in length. However, this is not correct – the company prefix can vary in length, depending on the number of SKUs the company needs to encode. A shorter company prefix allows more permutations for SKUs (and a higher price paid to GS1).

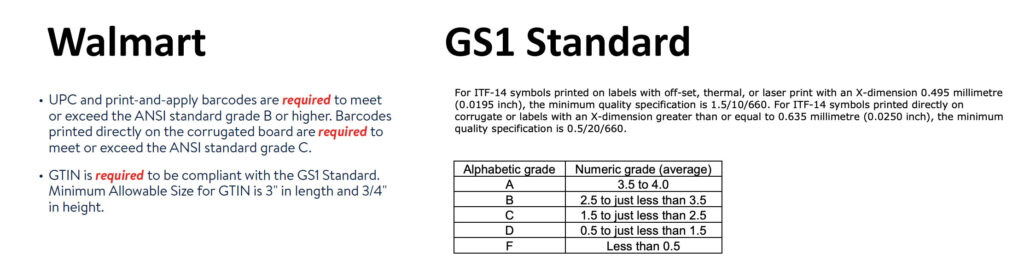

Another area where the Walmart and GS1 standards diverge is the required quality level.

This graphic is taken from the Walmart and the GS1 standard and shows that Walmart asks for higher quality scores than the GS1 standard.

Walmart (still using the old ANSI scale) demands grade B or better for UPC and print/apply barcodes and C or better for barcodes printed directly to corrugated materials.

On the other hand, the GS1 standard (refined after many years of practical industry experience) asks for Grade C or better for ITF-14 barcodes printed on labels and Grade D or better when the x-dimension of the barcode is greater than 0.025 inches or printed directly to corrugated.

As you can see from the image, immediately after stating a higher than GS1 quality standard, Walmart states that suppliers must follow GS1 standards in the next paragraph.

If you need to comply with Walmart’s labeling rules, you might want to discuss the required quality scores with your Walmart contact.

Note that GS1-128 barcodes are usually not recommended for directly printed on corrugated materials.

Do I need to have an RFID tag as well as a barcode?

The answer to this is that it depends on your product.

For some time, many types of clothing shipped to Walmart have needed to have EPC RFID tags, and more (such as sporting goods) are being added this year.

Most CPG and food products currently don’t need RFID tags, but this could change in the future.

Labeling for Walmart

Do you still have questions or need help with your labeling for Walmart and other retailers?

We are always happy to help, so please contact us at IDT@ProMachBuilt.com, and we’ll get you connected with the best person in your area!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.