Laser coders have become popular for printing variable information onto products and packaging.

There are certainly a lot of advantages – no consumables needed, high-quality permanent prints, and the ability to operate at high production rates.

Most lasers sold for packaging applications use CO2 laser light sources (like our SPA-C and iCON lasers) – usually a good choice because this technology works well on a wide range of substrates.

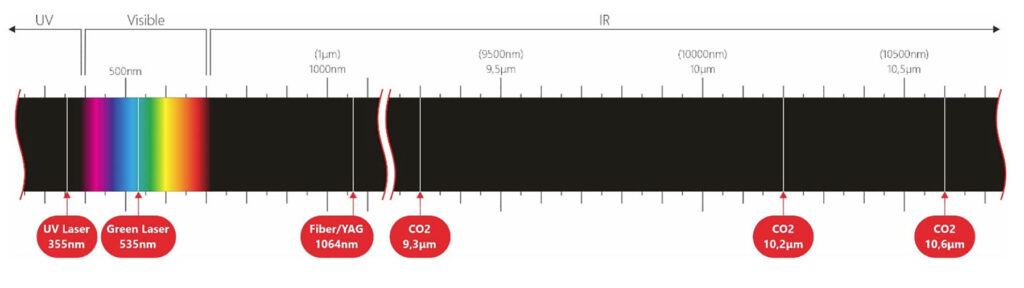

However, when a high contrast mark is required, not all materials will respond well to the CO2 laser wavelengths (usually 10.6 or 9.3μm), and a different laser light source is needed.

YAG and fiber lasers with a wavelength of 1,064nm (nanometers) are often used in industrial marking applications and sometimes in packaging as well – see ID Technology’s high-speed can coding system as an example.

The 1,064nm lasers can often produce a good mark on plastic materials, but some materials such as HDPE (high-density polyethylene) don’t respond with a high-contrast image.

HDPE and some other materials react well to the light emitted from green (532nm) and UV (355nm) wavelength lasers, and the results can be excellent.

In ID Technology’s lineup of D-5000 Series DPSS lasers, we offer systems for all three wavelengths, 1,064nm, 532nm, and 355nm.

The 1,064nm system is mainly used for industrial marking applications (although a fiber laser that operates at the same wavelength is more common). It is ideal for use in conjunction with our iLaserBox laser workstations.

This 1,064nm D-5000 laser is the parent device for green and UV lasers.

The 1,064nm light beam produced in D-5000 passes through a crystal that changes the light’s frequency (and, therefore, wavelength). Doubling the frequency results in the 532nm light for the green laser, and tripling it gives the 355nm of the UV laser.

Advantages of Green and UV Lasers

Green and UV lasers can print high-contrast marks on some plastics that other lasers cannot achieve – making them an obvious choice for some applications.

Like all lasers, they need no inks or chemicals, making them ideal for companies looking to enhance their green credentials.

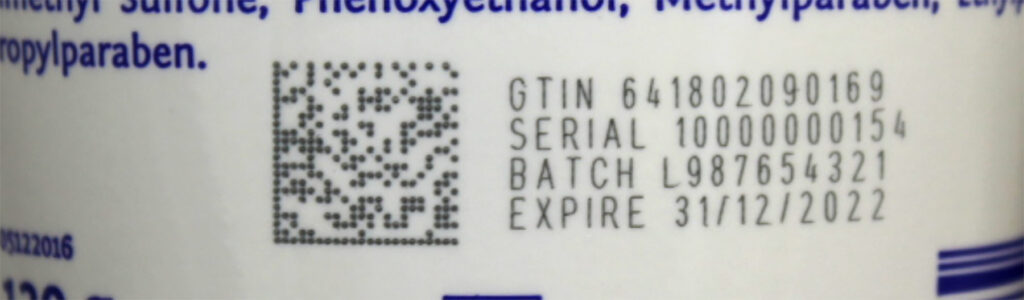

These lasers can print excellent quality barcodes, making them ideal for helping meet serialization and traceability requirements.

The downside of Green and UV Lasers

The main issue that needs to be considered when investing in green or UV laser technology is the ongoing operating cost.

One of the reasons fiber laser technology has often replaced DPSS for coding and marking is that the laser diodes that provide the light source for a DPSS laser need to be replaced periodically. However, the light source in a fiber laser operates for much longer before needing replacement.

Because the green and UV lasers are using DPSS technology, the cost of diode replacement needs to be factored into the purchasing decision.

Another factor is the crystal that magically changes the light frequency. These are exotic laboratory-grown crystals that lose effectiveness over time and need to be replaced, adding to the cost of ownership.

So Does Green or UV Make Sense?

When introducing any product technology, you need to look at all the factors that make a good decision.

- Which gives you the result you need?

- Which can keep up with the line speed?

- The actual cost of ownership, factoring in all the variables such as acquisition price, cost of consumables, cost of downtime, maintenance required, etc.

- And, of course, much more.

Which do I Need, Green or UV?

The best way to answer this is by testing.

Both green and UV lasers can do an excellent job coding on some packaging materials.

The UV laser is more versatile in the substrates it can handle, but the crystal used to triple the light frequency is more expensive than the one used in green lasers. If a green laser meets your present and planned future needs, it might be the best option.

We have a fully equipped laser testing lab so we can produce sample prints on your materials to determine which laser would be the best fit for your application.

What’s the Next Step?

If you are interested in exploring laser coding technology for your packaging, we’d love to help.

Contact us at IDT@ProMachBuilt.com to get started!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.