If you’ve been involved in packaging for any length of time, you’ll recall the big Walmart RFID fiasco of the early 2000s.

At that time, the giant retailer mandated that many vendors add EPC compliant RFID tags to shipping cases and pallets shipped to Walmart distribution centers.

The rationale behind this was that adding the ability to read data on the packages over a longer distance than could be achieved with barcodes would improve the management and traceability of these items as they traveled from manufacturer to retail store.

Early Failures.

This sounded great in theory, but there were some problems.

RFID labels were expensive. In many cases, blank RFID labels could cost up to $1.00 each. The infrastructure, readers, portals, software needed was expensive too.

Maybe Walmart would help pay for all this? Eh – no. And of course, there was minimal margin in many of these products to start with.

The RFID tags available at the time were not very reliable – I recall many rolls of RFID labels where more than half would refuse to be encoded, making them useless. In addition, of course, many labels that were successfully encoded failed to work when scanned in the supply chain.

All very frustrating, and Walmart backed down on the RFID mandate.

This didn’t mean that RFID was dead.

RFID Success.

The Department of Defense had a similar mandate to Walmart’s, which is in place today, and RFID has successfully been used for asset control in a wide range of applications.

We’ve also seen new growth in RFID in other applications.

Many companies, such as MacDonalds and Chipote, ask their suppliers to use RFID tags and barcodes on their packaging in foodservice supply chains.

With pharmaceutical companies often requiring extensive track and trace capability for their products, it’s no surprise that our colleagues at WLS have developed an RFID labeling system for that industry.

And now, after the original flirtations with the technology failed, many retailers have successfully used RFID to track clothing inventory.

One of these is Walmart which starting in 2020, mandated EPC RFID tags on clothing items, a process that is largely completed.

The company has noted that this was successful enough to increase the RFID requirement to include adding tags to sporting goods, homeware, and more, with a compliance date of September 2022.

How Can We Help?

Is your company being asked to provide RFID labeling to the products you sell?

At ProMach Labeling and Coding, our RFID experience goes back to the original Walmart and Department Mandates.

We can provide high-class solutions to make your RFID transaction easier.

Print and Apply Labeling Systems.

Our ID Technology and Panther labeling systems use the latest Zebra and Sato print engines – these can be specified with built-in RFID encoding – ready to encode your labels as they are printed.

The latest Zebra print engines can now encode small close-pitch inlays for more flexibility.

Tabletop RFID Printers.

The latest Zebra and Sato RFID printers are built to handle both RFID and conventional labels.

RFID Encoding Software.

Our NiceLabel and BarTender labeling software makes RFID label encoding simple as printing a barcode.

RFID SmartLabels.

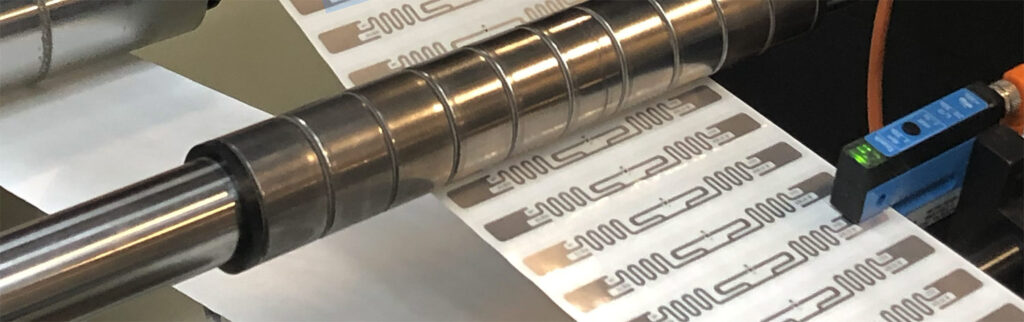

ID Technology manufactures RFID labels with several different inlay types, and we can even print them on our flexo press to enhance your labeling.

So, with RFID making advances in many applications, it might be a good time for you to investigate it again. We’ve come a long way!

How can we help make RFID Ride Again in your organization? Contact us at IDT@ProMachBuilt.com, and we’ll help you find out!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.