As tradeshows continue to come back to in-person, after the enforced Covid break, coming up in January is The International Production & Processing Expo, or IPPE.

The International Production & Processing Expo (IPPE) is a collaboration of three shows – International Feed Expo, International Meat Expo and the International Poultry Expo – showcasing the latest technology, equipment, supplies and services used in the production and processing of eggs, meat and poultry, and those involved in animal food manufacturing.

The meat and poultry business was often in the news during Covid, especially at the beginning, but the industry was able to keep supermarket shelves stocked with their products – that so many of us depend on.

Our ProMach Labeling & Coding team is excited to be exhibiting at IPPE this year (we’ll be at booth BC10213), with a full line-up of solutions for the protein industry – whether you need to label your products, add date and production codes, or print and apply labels to your secondary packaging (or pallets), you’ll find something that will help.

Print and Apply Labeling Systems.

Integrated Case Taper and Labeler.

What do you get when you combine a Bel 150 or 250 case taping system with ID Technology’s market-leading print and apply labeling machine? A completely integrated sealing and labeling solution for your corrugated cases, that saves on space and reduces setup time.

We’ll be showing the system at IPPE sealing the top and bottom of cases, then printing and applying a label to two sides. In addition, the CTL can also be outfitted with our ProSeries hi-resolution inkjet printheads as an alternative to labeling.

The CTL system to be shown at IPPE will incorporate both technologies.

252 PowerMerge™

ID Technology’s PowerMerge applicator system is designed to improve efficiency and increase outputs by de-coupling the thermal print engine from the label application process.

This allows the printer to operate at a lower print speed than on conventional labelers, leading to less wear on components (and less need for parts and maintenance), along with better barcode quality.

The PowerMerge applicator can apply labels up to 14 inches long, making it ideal for corner-wrap labeling.

At IPPE, we’ll be showing a 252 print/apply unit, using its PowerMerge to apply two labels (or one label and a packing list) to the side of a corrugated case.

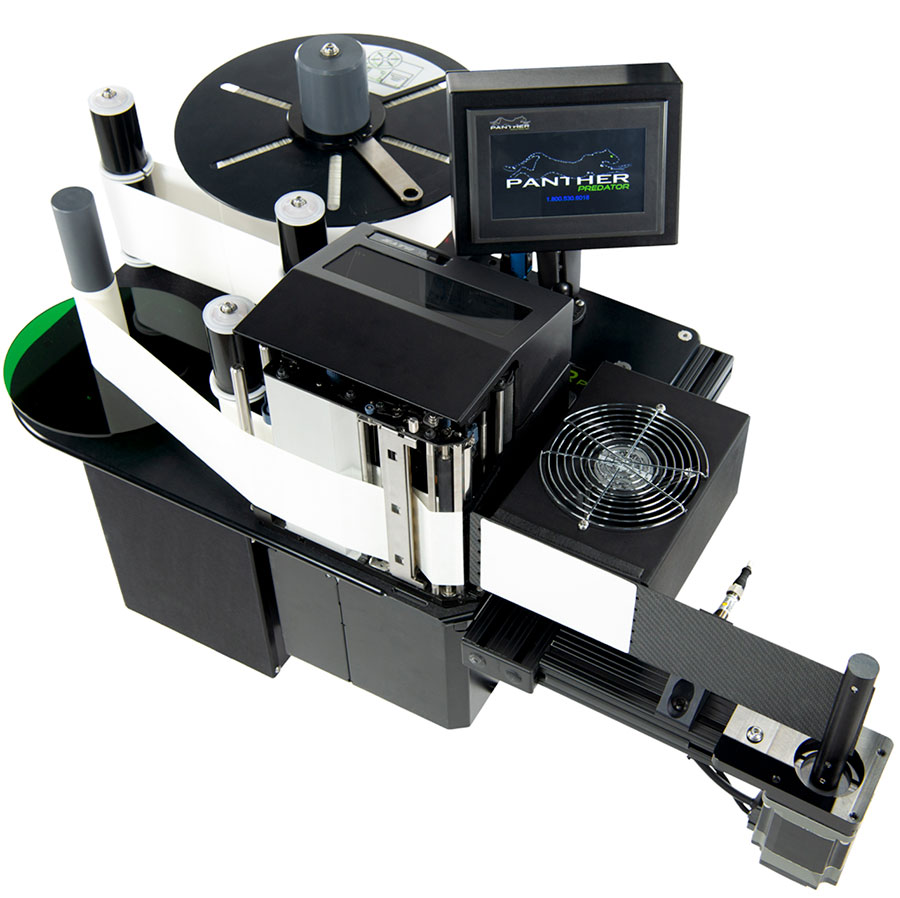

Panther CarbonFlex

The CarbonFlex applicator is designed to apply one or two labels to shipping cases, trays or pallets.

Requiring no compressed air, the low mass carbon fiber blade applicator is servo-controlled, ensuring complete control of the labeling process.

As well as being simple to install and set up, the CarbonFlex concept is more forgiving of variations in product handling than many other types of applicator.

ID Technology Direct Thermal and Thermal Transfer Labels.

When it comes to producing perfectly labeled packages with compliant GS1 barcodes, using ID Technology labels is the way to success.

With 7 label production plants in the US and Canada, ID Technology offers national-level support, with local service.

Major investments in equipment and people ensure we can keep your production running – even in challenging times.

If you use our labels on your ID Technology labeling equipment, you’ll also qualify for our limited equipment warranty – just ask us how!

If you are going to attend the show, we’d love to see you at booth BC10213. Should you not be going, but would still like to improve your labeling operations, just contact me at David.Holliday@ProMachBuilt.com and we’ll get one of our local experts to help you get started!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.