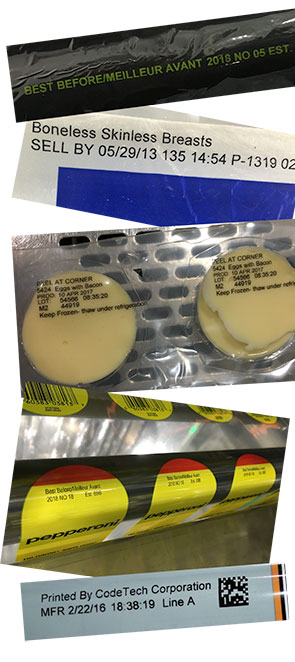

Regardless of package type, companies that produce meat or poultry products need to add variable information to the package. This includes date and lot codes, establishment codes, regulatory agency logos, and increasingly barcodes.

In many industries, this is quite straightforward, but for protein companies, there is the added complication of the environment in which coding and packaging equipment has to operate. Cold and wet conditions are the norm and any equipment brought into the plants needs to be able to handle this as well as washdown situations.

Traditionally continuous inkjet (CIJ) printers have been used for printing variable information onto meat and poultry packaging. These printers can usually handle the harsh conditions found on the packaging lines and also produce the print quality that is good enough for the applications. Thermal inkjet (TIJ) printers have not been used in the past due to the inks being unsuitable for use on the films used for the packaging.

Over the last few years, however, there have been great advances in the chemistry of inks for TIJ printing and today, this technology is proving to be very successful at printing onto the non-porous substrates used for protein packaging.

The ink cartridges used in thermal inkjet printers ensure that there is no need to have to deal with the MEK and other solvents used in other print technologies, such as CIJ. There is no need to deal with disposing of partially used ink or additive bottles.

With no cleaning cycle needed at startup or shutdown, a thermal inkjet printer is always ready to work.

The thermal inkjet coders provided by ProMach brands, Code Tech & ID Technology, are designed to be able to get the job done in these areas. They bring all the advantages of the thermal inkjet system but include models that are available in IP65 versions, perfect for producing excellent code quality every time, regardless of the environment.

Reduce Maintenance & Downtime

A thermal impact printer uses familiar HP type ink cartridges. This means that every time you change the cartridge, you effectively get a new printer.

As a bonus, should you need to change the color of your print, this is accomplished by simply replacing the ink cartridge with one of the required color.

Our TIJ printers come in versions that are built to IP65 environmental protection. This means that regardless of how dirty or wet the packaging environment, the printers will operate happily.

Exceptional Print Quality

With print resolutions of up to 600×600 DPI, thermal inkjet produces perfect prints every time, even when printing very small fonts or high-density barcodes.

Inks are available that are fast drying and durable to suit just about every packaging material.

Quick and Simple Installation and Integration

Thermal inkjet printers from ID Technology and Code Tech have a small footprint, making them easy to install in your parent packaging machine, even when multiple heads are needed.

Combined with the web handling and printer traversing expertise of the Greydon brand, printers from ProMach Labeling & Coding can be integrated with every type of flexible packaging machine.

Is TIJ Always the Best Technology to Use?

No, not always.

Thermal inkjet brings some important advantages, but there are times where an alternative technology such as CIJ printing, thermal transfer, laser or ink stamping might make sense. We happen to sell a complete range of coding technologies so we can work with you to help decide which is best for your unique needs.

Want to Get Started?

How can you start improving your own packaging coding? Contact us today at 888-438-3242 Option#3. You can also email me at dholliday@idtechnology.com We’ll get you in touch with one of our local experts right away.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.