These days just about every brand is involved in e-commerce, whether it is selling online directly to end-users, via retailers online sites or through Amazon’s “Fulfillment by Amazon” (FBA) program. It is estimated that for 2018 US total e-commerce sales will be over $400bn, growing to over $650bn by 2020 (source: PMMI). At the moment, this is less than 10% of total retail sales, so there is plenty of scope to grow.

These days just about every brand is involved in e-commerce, whether it is selling online directly to end-users, via retailers online sites or through Amazon’s “Fulfillment by Amazon” (FBA) program. It is estimated that for 2018 US total e-commerce sales will be over $400bn, growing to over $650bn by 2020 (source: PMMI). At the moment, this is less than 10% of total retail sales, so there is plenty of scope to grow.

How are Brand Owners Adopting Packaging to E-Commerce?

To meet the demands of both customers and the E-Commerce supply chains, companies are making several changes to their packaging. These include:

Smaller pack counts – this means packaging and labeling equipment must be able to operate at higher speeds than in the past.

Moving to shrink-wrapped trays – usually causes a change in labeling equipment or barcode printing capability.

Reducing costs by printing directly onto corrugated

How do ID Technology and Panther help?

E-Commerce logistics rely on accurate barcoding to be able to keep track of every item as it moves from manufacturer to DC/Fulfillment Center and through the steps to the final customer.

ID Technology and Panther label printer applicators are well proven in this industry and have the speed and flexibility to meet the demands of even the toughest logistics applications.

When it comes to labeling variable height products for e-commerce and logistics, our Panther Preditor is the best in the industry.

It integrates into your warehouse execution software (these machines are sold via the warehouse/Fulfillment Center integrators) and applies license plate barcodes to the incoming packages, right at the start of the operation, as well as being used for shipping labels and other applications.

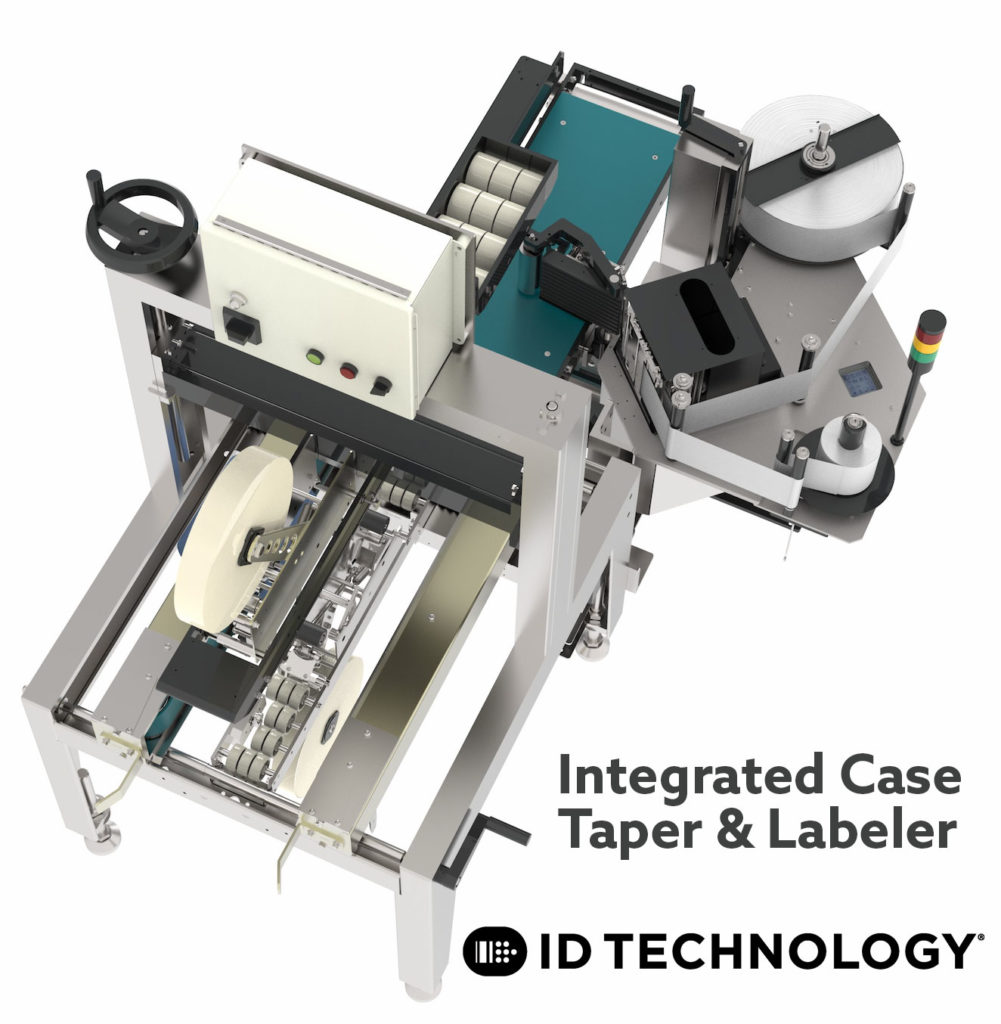

ID Technology also has great options for barcode labeling on cases, cartons, and pallets to ensure they meet all the requirements for label position and barcode quality. A great example is our CTL system that combines case sealing (loading too, with additional options), with print/apply labeling, all in one compact machine.

ID Technology labeling systems are designed to work as hard as your distribution center and can be configured to apply labels to one or more sides of the case, tray or pallet.

Handling Labeling and Packing Lists

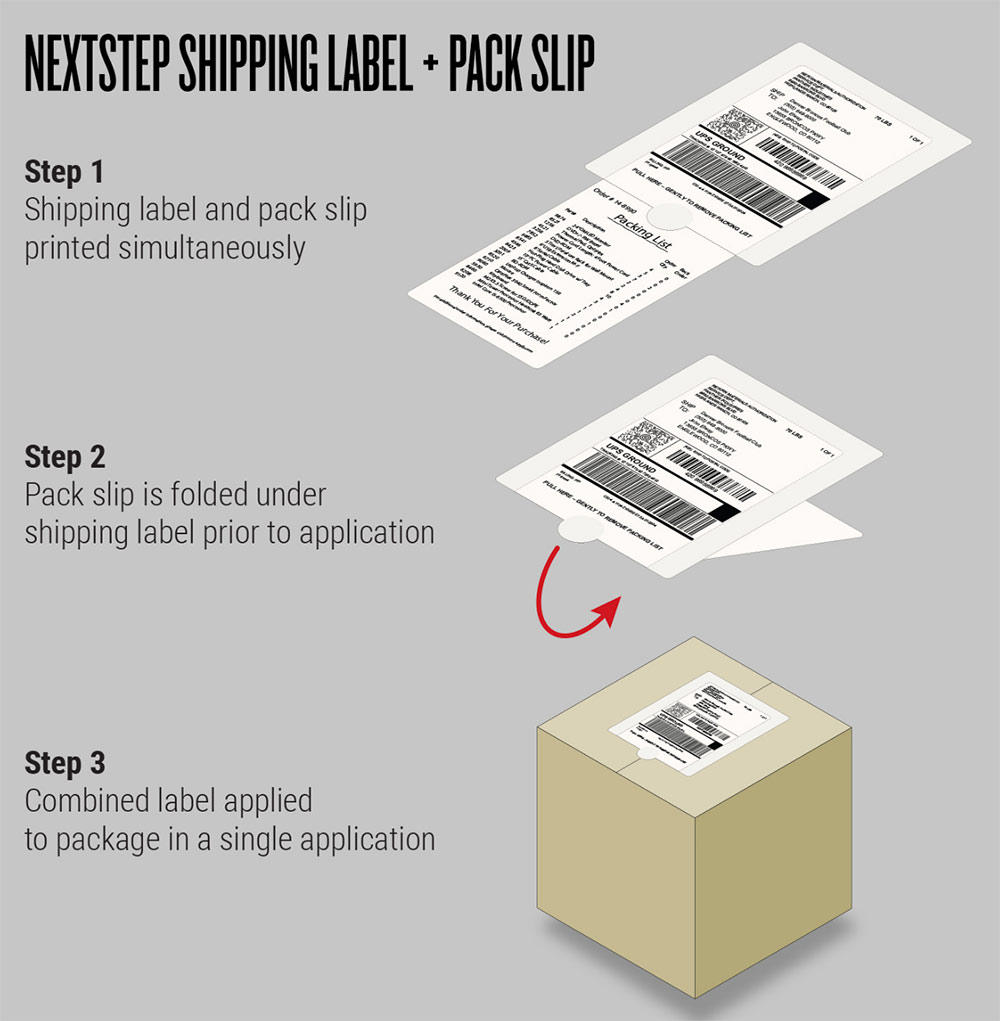

Do you need to include packing lists or invoices with your shipment?

Our Panther team has developed a range of helpful solutions, including NEXTStep, a means to print both items and automatically apply to your packaging:

Labeling Flexible Packaging

As companies work to reduce costs and produce packaging that works well for their customers, flexible packaging is a growth area in the e-commerce world.

ProMach brands Texwrap and Rennco, both make wrapping systems that are well suited for use in fulfillment centers:

Texwrap 3322 AutoMailer with ID Technology Labeler

The 332 is designed to wrap products of random sizes and produce a finished ready to mail package at a rate of up to 20 per minute.

As the product enters the system, a barcode scanner reads a license plate barcode on the product and the shipping label details are retrieved from the warehouse software. Sensors on the 3322 also accurately measure the size of the product so that the optimum sized package is produced.

Once the product is wrapped, the address label is printed and applied by the ID Technology 252 labeling system.

Rennco 301 Bagging System

The Rennco system is perfect for when a number of items need to be shipped to the same address. Traditionally, this kind of packaging would have used boxes, but switching to bags saves costs on both packaging and shipping.

When the tote containing the products arrives at the machine, the barcode on the tote is read, allowing all the shipment data to be retrieved from the database. The 301 produces the correct size bag to secure the items and use a minimal amount of material.

The address label for the bag is automatically printed and applied using an integrated ID Technology 252 labeling system, ensuring that the finished bag is ready for mailing.

Printing Directly on Corrugated

According to PMMI’s 2018 eCommerce report, 18% of companies see printing directly onto corrugated as something that is changing packaging.

For this application, ID Technology provides the Foxjet Pro-Series inkjet printer, a well-proven printing solution that combines the lowest possible print pricing with excellent quality and high-speed operation.

Continued Innovation

As e-commerce continues to grow and the needs of brand owners, logistics companies and customers evolve, you can be sure that ID Technology and the other ProMach brands will continue to develop solutions to help keep your products flowing to your customers.

How can ID Technology and ProMach help you meet your objectives for your e-commerce operations? Contact us today at IDT@ProMachBuilt.com. We’ll be sure to get you in touch with an expert, right in your area!

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.